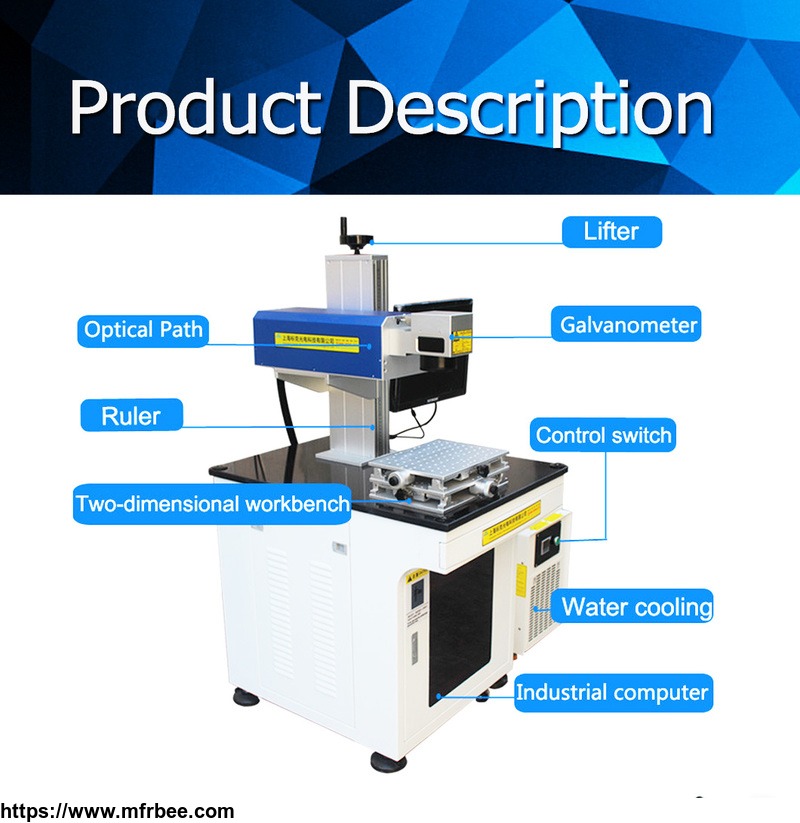

355nm 3W/5W/8W/10W UV Laser Marking Machine with Best Quality

Product Quick Detail

- FOB Price

- USD $15,236.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Power Supply

- 90-260V/50Hz-60Hz

- Repeating Accuracy

- ±0.003

- Marking Depth

- <0.3

- Operating System

- Windows 7

- Min Line Width

- 0.005mm

- Laser Source

- Max, Ipg

- Marking Scope

- 110*110mm(Standard)

- Min Character

- 0.15mm

- Control System

- Bjjcz/Ezcad

- Warranty

- 2 Years

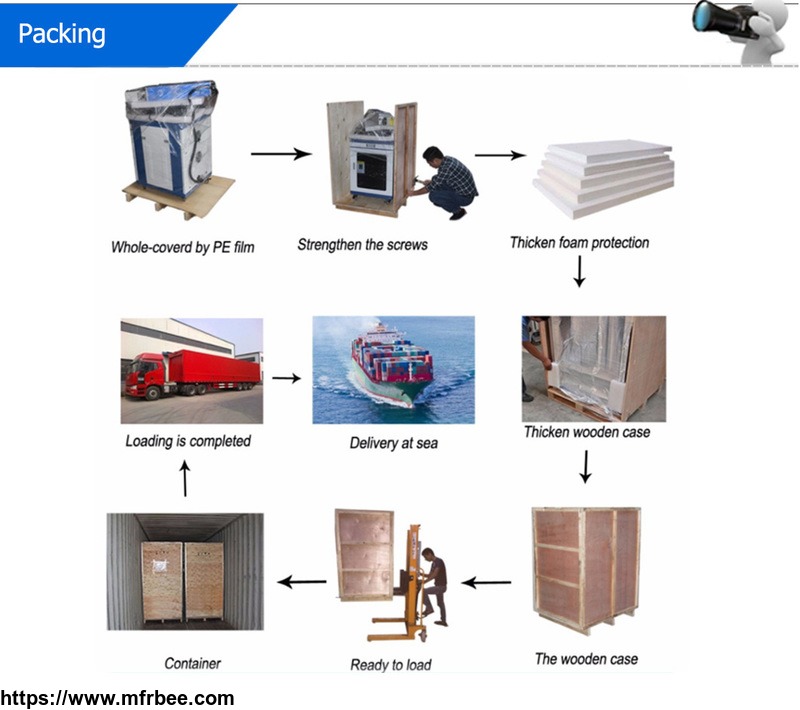

- Packaging

- 1piece each container

- Delivery

- 5 Days

Specifications

Technical Parameters:

Characteristics:

1. High beam quality, and the spot is very small, can achieve ultra-fine marking;

2. Almost perfect marking quality: 355nm output wavelength to reduce the thermal impact on the

workpiece; galvanometer high-precision marking head, marking the effect of fine and repeatable;

high-precision fine spot to ensure the perfect marking results; marking the process of non-contact,

marking effect is permanent;

3. UV laser marking machine for a large range;

4. Heat affected area is very small, there will be no thermal effect, the material is not deformed not

charred;

5. Marked fast, high efficiency;

6. Machine performance is stable, small size, low power consumption;

7. More suitable for the heat radiation reaction of large materials processing; with the production

line with, automatic loading and unloading, automatic access to materials; suitable for the vast

majority of metal and non-metallic materials on the marking;

8. Flexible and convenient operating system: the operation process is humanized, Equipment

operation is stable;

9. Dedicated control software is compatible with AutoCAD, CorelDRAW, Photoshop and other

software output;

10. Can support the PLT, PCX, DXF, BMP, JPG and other file formats, you can directly use the TTF

font; CCD automatically identify and position the track (Figure), can be used to automatically

identify the track, graphics, bar code, two-dimensional code, serial number and other automatic

scheduling and modification.

| Model | BK-ZW3W/5W/8W/10W |

| Power | 3W/5W/8W |

| Laser wavelength | 355nm |

| Beam quality | M2 <1.1 |

| Laser output power | 0~100% (continuous and adjustable) |

| Laser output frequency | 5KHz~80KHz (continuous and adjustable) |

| Power stability(8h) | <�±1%rms |

| Pulse width | 10-50ns |

| Spot diameter | <0.01mm |

| Tag type | Dynamic tag / static tag |

| Marking speed | 800 standard characters per second |

| Min line width | ≤0.005mm |

| Min character | 0.15mm |

| Repeat accuracy | ±0.003mm |

| Production pass rate | 99.9% |

| Operate system | WindowsXP |

| Cooling method | Air-cooled |

| Operating ambient temperature | 15ºC~35ºC |

| Power supply | 220V/single-phase/50Hz/<800W |

| Laser module life | 20000 hours |

Characteristics:

1. High beam quality, and the spot is very small, can achieve ultra-fine marking;

2. Almost perfect marking quality: 355nm output wavelength to reduce the thermal impact on the

workpiece; galvanometer high-precision marking head, marking the effect of fine and repeatable;

high-precision fine spot to ensure the perfect marking results; marking the process of non-contact,

marking effect is permanent;

3. UV laser marking machine for a large range;

4. Heat affected area is very small, there will be no thermal effect, the material is not deformed not

charred;

5. Marked fast, high efficiency;

6. Machine performance is stable, small size, low power consumption;

7. More suitable for the heat radiation reaction of large materials processing; with the production

line with, automatic loading and unloading, automatic access to materials; suitable for the vast

majority of metal and non-metallic materials on the marking;

8. Flexible and convenient operating system: the operation process is humanized, Equipment

operation is stable;

9. Dedicated control software is compatible with AutoCAD, CorelDRAW, Photoshop and other

software output;

10. Can support the PLT, PCX, DXF, BMP, JPG and other file formats, you can directly use the TTF

font; CCD automatically identify and position the track (Figure), can be used to automatically

identify the track, graphics, bar code, two-dimensional code, serial number and other automatic

scheduling and modification.

Pre-sales service

a.Inquiring and consulting support

b.Sample testing support

c.Visiting our factory

After-sales services

a.2year guarantee period for product quality

b.Free training for machines installation and operation

c.Lifelong maintenance and spare parts supply

a.Inquiring and consulting support

b.Sample testing support

c.Visiting our factory

After-sales services

a.2year guarantee period for product quality

b.Free training for machines installation and operation

c.Lifelong maintenance and spare parts supply

- Country: China (Mainland)

- Business Type: Buying Office,Manufacturer,Distributor/Wholesaler,Trading Company,Retailer,Broker, Consultant commission-based,Government Agency / Organization

- Market: Africa,Americas,Asia,Emerging Markets,Europe,European Union,G20,Middle East,Oceania

- Founded Year: 2005

- Address: No.8,Ning,an Road,Xiaoshan Economic Development Zone

- Contact: Wang Collen