Screen Gaskets for Food and Beverage Industries

Specifications

Screen Gaskets for Food and Beverage Industries

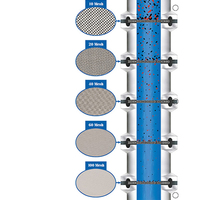

Screen gasket consists two parts, one is the elastomer gasket external part, and in most cases its section is a standard Tri-Clamp. The gasket part is connected with a stainless steel screen or perforatedstainless steel plate as inner part

Screen gasket can resist low and high temperature and anti-aging, and they can be used in pharmaceutical, food and chemical applications.

Screen gaskets have various applications and their mesh count ranges from 10 to 400 to satisfy different filtration purpose.

Screen gasket can also have metallic gasket ring to seal the gap, and it is acid and alkaline resistant.

Sock screen gasket generally has 300% more open area which means 300% more particle collection capability than conventional screen gasket.

A fine particulate elimination system made of comprehensive range of mesh screens can effectively

Applications:

- Our screen gaskets have various applications in our daily life. Protecting sensitive pieces of process equipment, such as spray balls, spray nozzles, filling needles, pumps, one-way valves and accessories.By separating the volume of solids out of the process stream.

- They can also be used for pre-filtration in thin-film filters, coalescence of water vapor from process lines, remove the large particulate before fill and finish process as well as disinfection process, and chromatography purification.

| Materials | Usages |

|---|---|

| Buna | Widely used in the food and beverage industries, and the economical choice for seals in engines and equipment where petroleum based oils, lubricants, and fuels are present. Never use Buna gaskets for ozone, ketones, esters and aldehydes. |

| PTFE | Widely used in pharmaceutical, food and chemical applications. |

| Silicone | Widely used in pharmaceutical, high- purity water, injectable, food and beverage applications. |

| Orifice plate | Sanitary orifice plates are widely used in a sanitary process line to constrict or flow downstream, or to maintain a constant pressure upstream. |

- Contact: xiaoyan QI