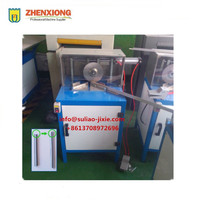

Refrigerator door gasket welding machine

Product Quick Detail

- FOB Price

- USD $6,500.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- wood package

- Delivery

- 30 Days

Specifications

This fridge door gasket welding machine is specially used in welding refrigerator door gasket, rubber gasket, which has the features of compact structure, easy operation and accurate temperature controlling. The heating tube is made of imported materials. One leg period of this machine is about 14 seconds and the leg stretching resistance is higher than the technical standard in the same industry at home and abroad.

Feature:

(1) This machine adopts advanced Omron PLC control system, famous-brand cylinder, and imported electrical parts to keep machine high-automatic, high-efficient, easy operation, long-using time.

(2) This machine can weld 2 gasket corners every time, after welding, it cleans (trims) rest material automatically to keep even, firm and beautiful surface of welding corner.

(3) The welding process is: heating ~ vacuum adsorption ~ welding ~ inner cooling ~ outer cooling ~ automatic outlet.

(4) the welding mould take with vacuum system, and inner cooling system, which can make the gaket corner smooth surfact and the inncer cooling systme can avoid gasket zones stick together.

(5) Photoelectrical protection system is used to protect hands being clamped in operation.

(6) Welding period is 11~14 second/ two corners, the output can reach 600~650 sets per 10 hours.

(7) This machine pass CE certification and export to different countries.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Europe

- Founded Year: 2006

- Contact: Aaron Dai