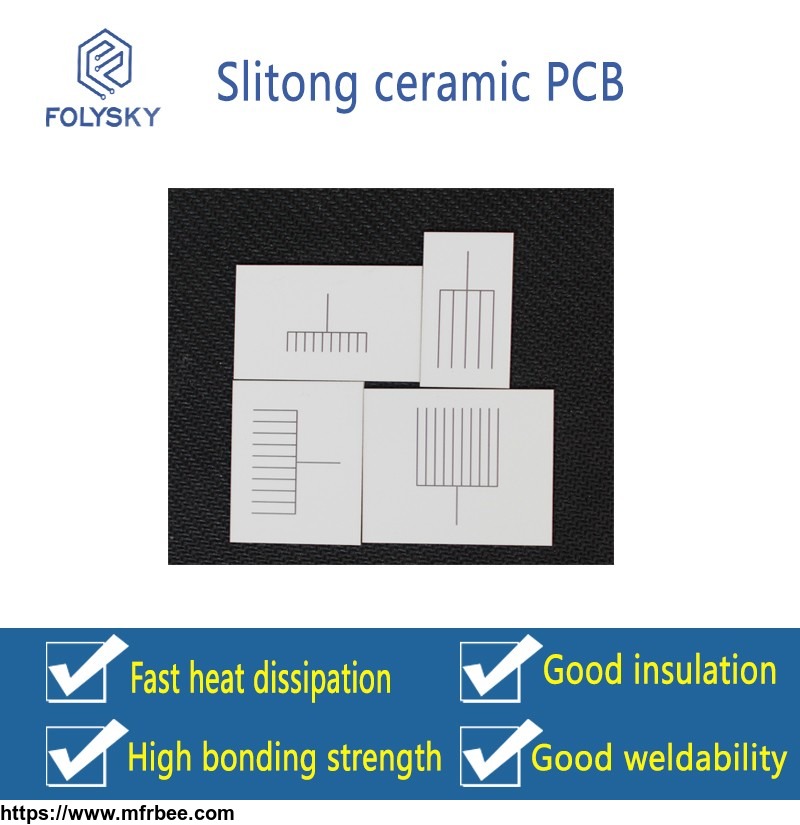

Ceramic Circuit Board Drilling Cutting Ceramics Metallization-Slitong

Specifications

Ceramic circuit board precision laser cutting technique: irradiated under the laser beam, the femtosecond pulsed laser makes the energy rapidly infuse into the tiny area (10μm) in the peak power; the

sedimentation of high energy density makes the change of the electronic absorption and movement modes, avoiding laser linear absorption, energy transfer and diffusion, as well as, fundamentally

changing the interaction mechanism between laser and ceramic. The material of ceramic circuit, transiently heated by the high peak power and rising to the gasification temperature, is not going to

melt prominently, which makes the material escape from the surface of the material in the form of gas. After reflected by the high displacement scanning mirror, the laser beam focuses on the surface

of the ceramic circuit board via the flat field mirror and multiplicating rotation, gradually etches, thoroughly cuts and separates the material at last.

- Contact: pengliang Tu