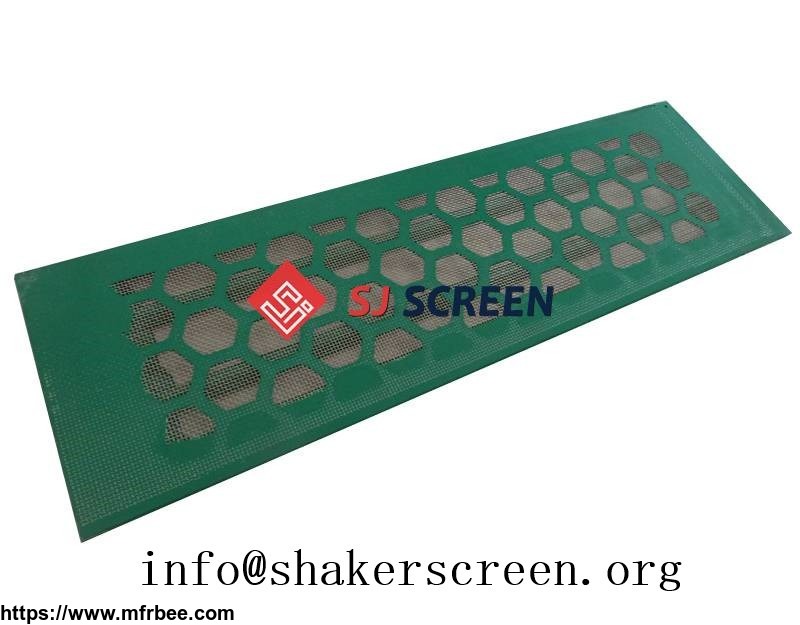

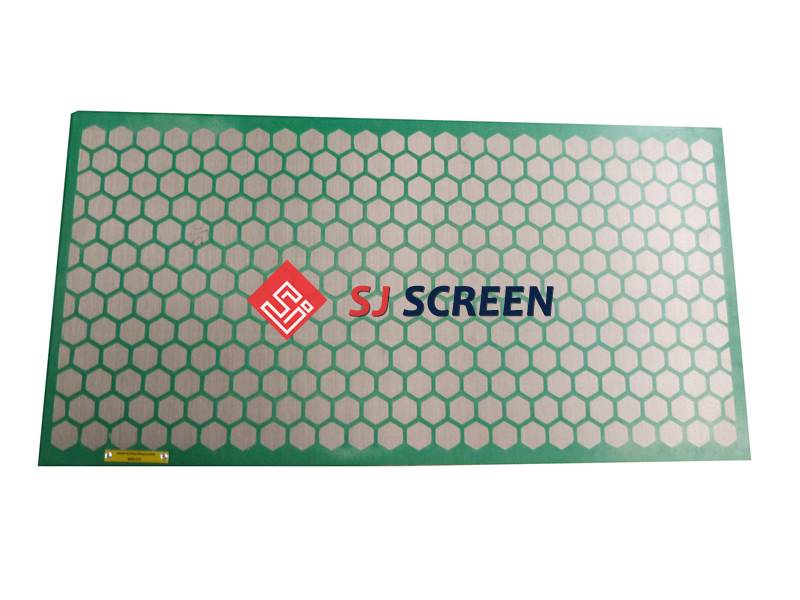

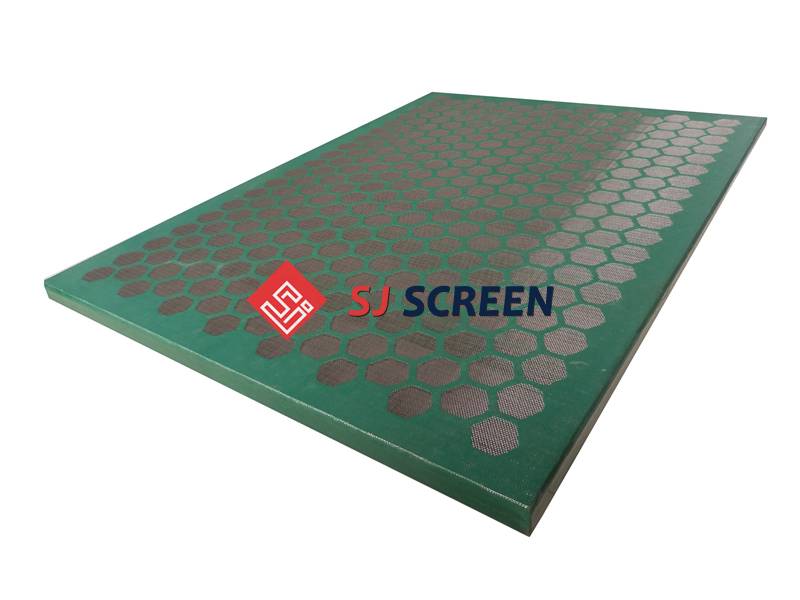

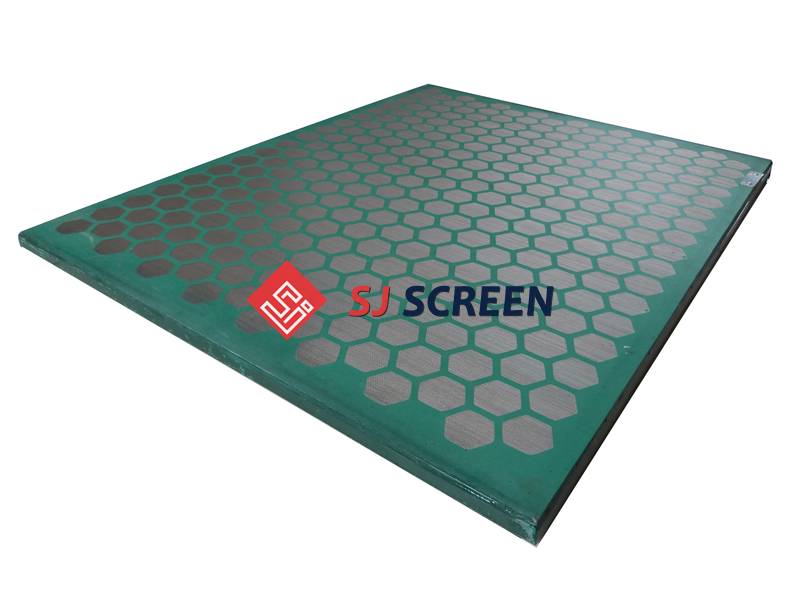

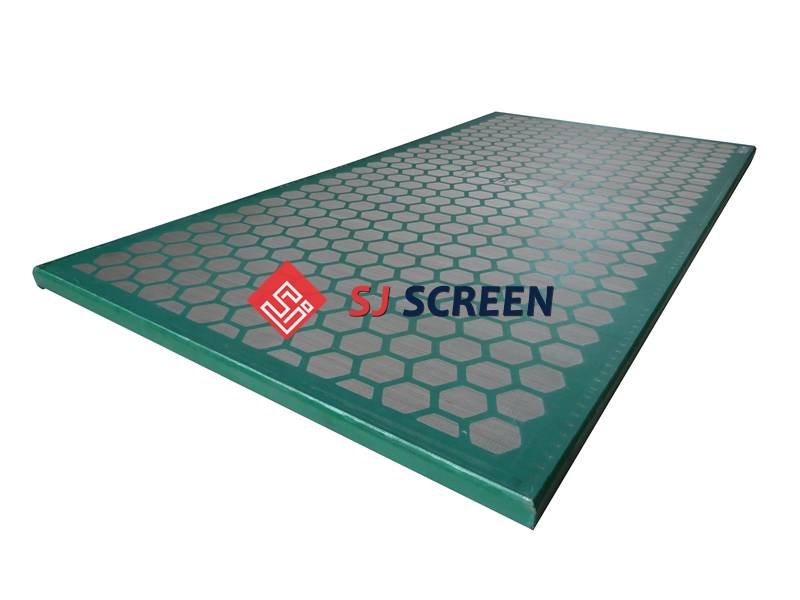

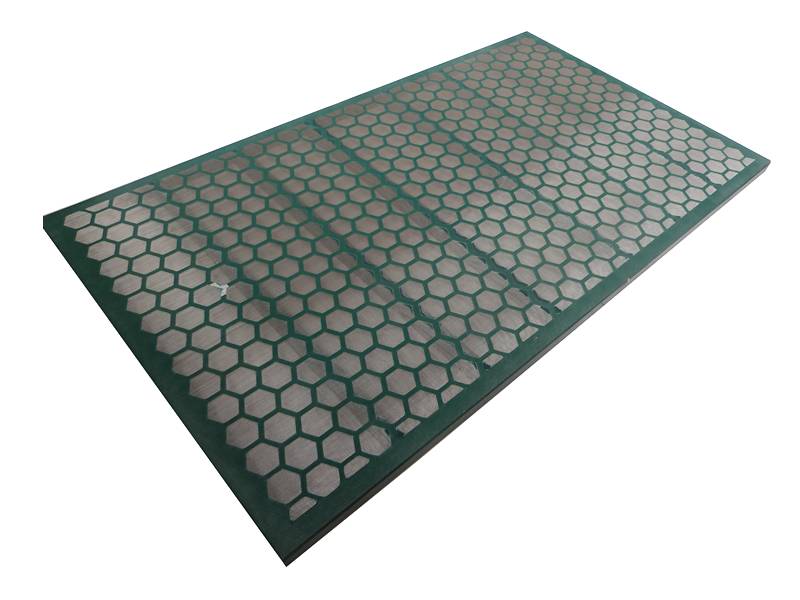

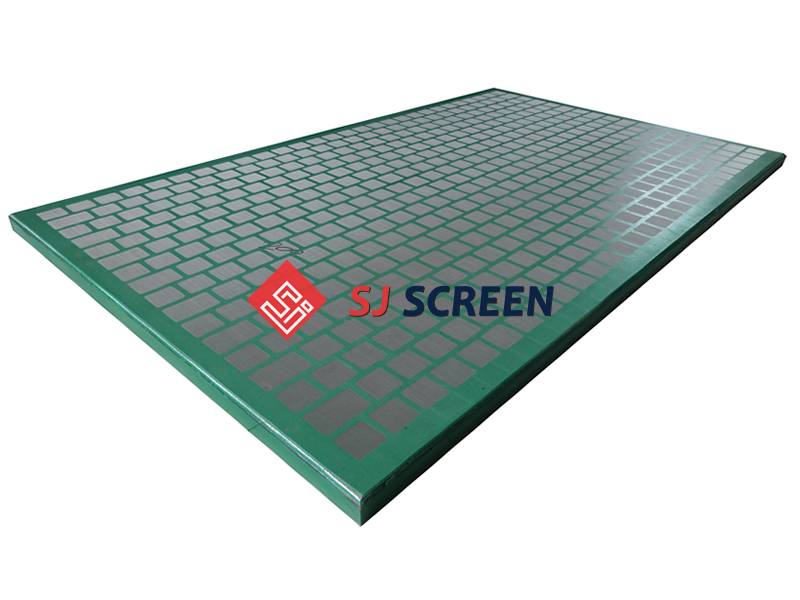

Steel Frame Shaker Screen

Product Quick Detail

- FOB Price

- USD $10.00 / Piece

- Minimum Order

- 100

- Place Of Origin

- China

- Packaging

- Packed in paper carton, shipped by wooden case

- Delivery

- 15 Days

Specifications

Steel Frame Shaker Screen for Oil Vibrating Application

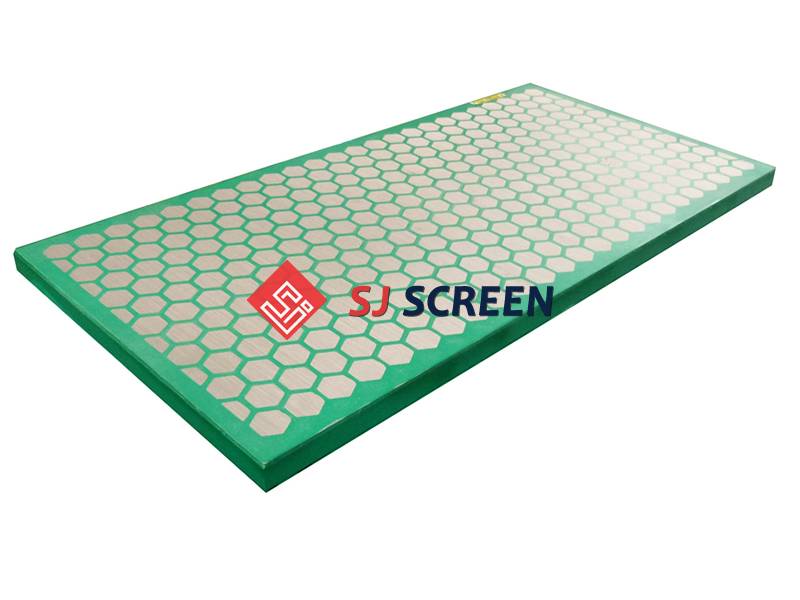

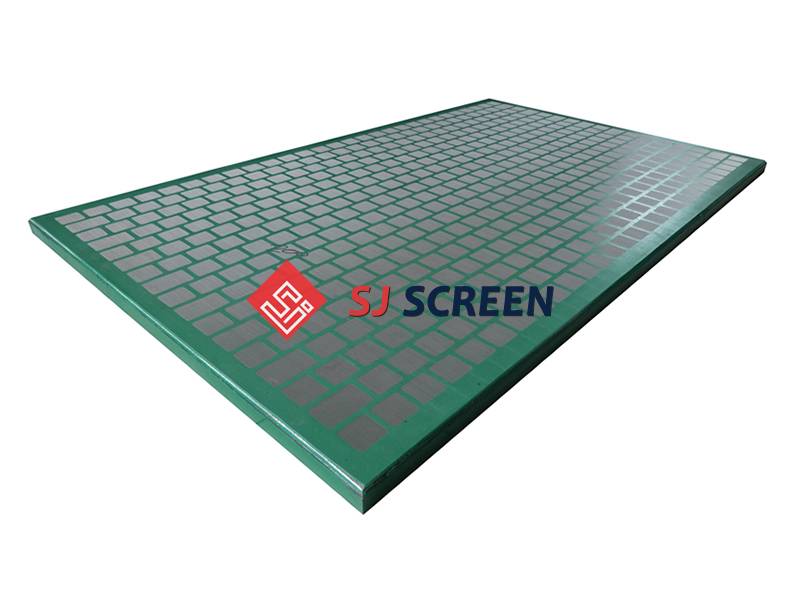

Steel frame shale shaker screen consists of two or three layers of stainless steel wire mesh. Its supporting layer and working layer bonded together to make the screen more durable. The whole screen is divided into many independent small meshes to prevent the excessive extension caused by partial damages. Meantime, the specialized rubber plugs can repair timely. This effectively saves time and reduces disposal costs.

Compared with flat shaker screen and hook strip flat screen, steel frame shale shaker screen has higher strength and better abrasive resistance. The high strength steel frame and supporting grids of the screen forms a reliable and stable structure. Thus greatly increases the shaker screen's loading capacity and operational efficiency.

Specification

- Material: stainless steel wire.

- Screen layers: two or three.

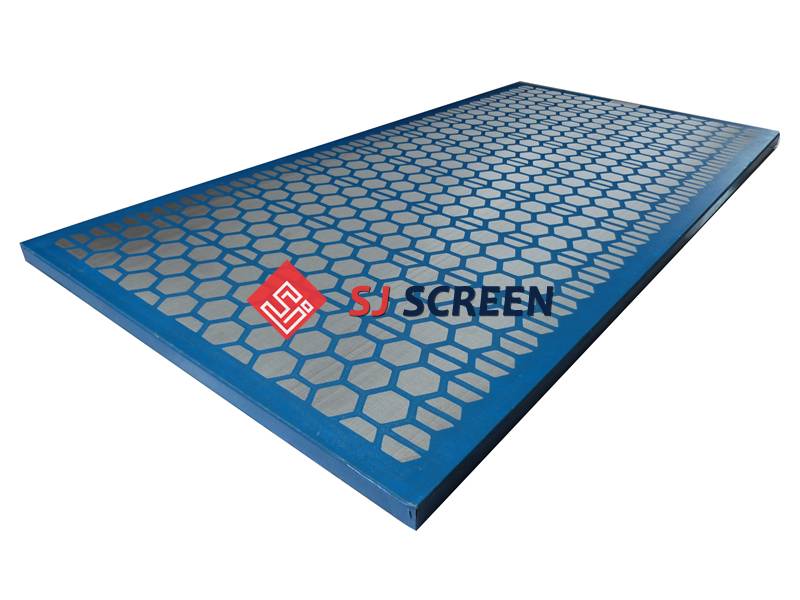

- Colors: black, blue, red, gray, etc.

| Screen Model | Range of Mesh | Dimension (length × width) | Weight (kg) |

|---|---|---|---|

| SFSS-1 | 16 - 325 | 585 × 1170mm | 12 |

| SFSS-2 | 16 - 325 | 635 × 1253mm | 13.5 |

| SFSS-3 | 16 - 325 | 913 × 650mm | 12.5 |

| SFSS-4 | 16 - 325 | 720 × 1220mm | 17 |

| SFSS-5 | 16 - 325 | 712 × 1181mm | 17 |

The replacement screens can be specifically designed to fit various shale shakers. Specifications can be customized according to your needs.

Advantage

- High-strength steel frame; excellent wear resistance.

- Solid structure; good loading capacity.

- Effective panel pressure distribution system.

- Superior screening performance; higher working efficiency.

- Effective plug repair system; less downtime.

- Available in various colors.

- Lower overall operational cost; economical.

Application

- Removing solids from drilling fluid.

- Used as oil vibrating screen for various shakers.

- Used in the oil industry for solid-liquid separation.

Tell Us Your Request and Get a Free Quote

TO: info@shakerscreen.org

- Country: China (Mainland)

- Market: Asia,Americas,Emerging Markets,Middle East

- Founded Year: 1989

- Address: Huangcheng Industrial Zone of AnPing County, Hebei, China.

- Contact: YUN LI