Automatic Laminating machines MODEL YFMD -iseef.com

Specifications

Instruction:

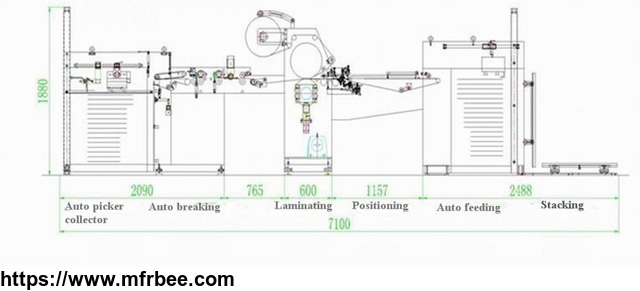

YFMD Automatic Laminating Machine apply to the equipment complex of BOPP thermal lamination film and paper. It is consisted of auto feeding system, positioning, laminating system, auto breaking and auto picker collector.

It is a new type of after-print laminating machine. The machine centralizes the features of compact structure, high automation, humanized operation design.

Application:

The machine widely used in textbooks, books, calendars, cards, product samples, packaging Box etc. It is an excellent choice for printing and packaging factory, professional after-print laminating factory and so on. Which can improve printing quality and decrease the technical cost.

Process:

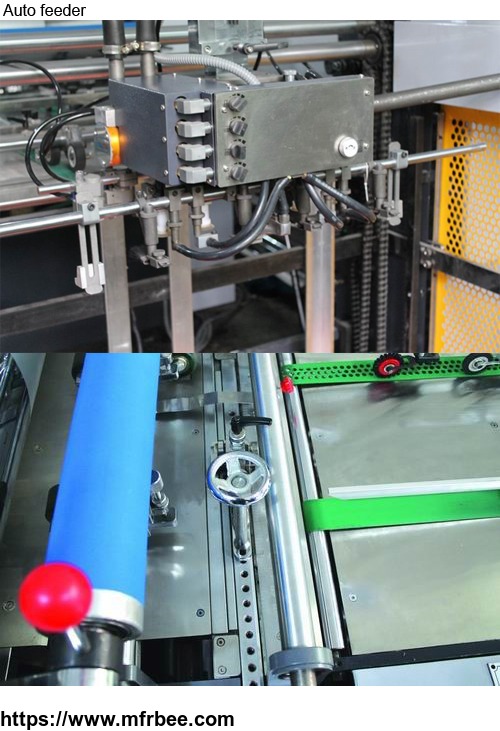

BOPP or non-glue plastic film convey from release air shaft, through the convey roller and curved roller, in the meanwhile automatic conveyor automatically sent paper to laminating machine host. It adopts heating roller and pressure way to laminating BOPP film and non-glue film on paper.

Heating roll adopts oil heating system to homogenize and stabilize laminating temperature. The laminated goods will be auto breaking and then to automatic picker collector to finish collecting.

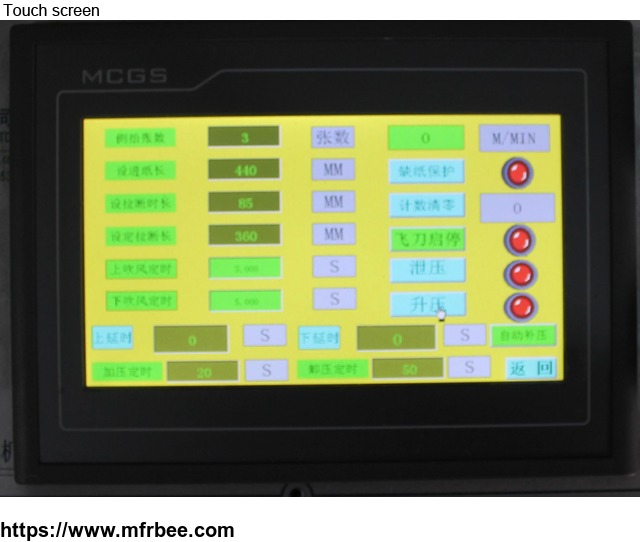

PLC control system:

The electric and pneumatic devices are controlled by programmable control system(PLC), main components adopt international brands, need one person to operate.

User only need to input processing paper size on the text screen, then can achieve film laminating and paper slitting.

The equipment is very suitable for large size laminating companies.

Main device:

-Auto feeding

-Auto breaking

-Auto picker collector

-PLC control system

-Anti curved device

-Electromagnetic heating system

-Push and pull registration

Optional device with surcharge:

-Automatic Powder cleaner

-Chrome-plating double roller

-Circulation hot water temperature controller

Main technical parameter:

| Model: | YFMD-1100 | YFMD-1200 | YFMD-1450 |

| Max. Paper Size(W*L): | 1080*940mm | 1080*1200mm | 1092*1450mm |

| Min. Paper Size(W*L): | 300*300mm | 350*350mm | 400*500mm |

| Machine speed: | 0-80m/min | 0-80m/min | 0-80m/min |

| Paper gsm: | 120-500gsm | 120-500gsm | 120-500gsm |

| Machine temperature: | 80-130℃ | 80-130℃ | 80-130℃ |

| Laminating roller diameter: | Φ400mm | Φ400mm | Φ400mm |

| Machine power: | 23kw | 26kw | 26kw |

| Weight: | 4000kgs | 4800kgs | 5500kgs |

| Machine Dimension w/ auto picker collector: | 7100*2000*1900mm | 7300*2000*1900mm | 8000*2000*1900mm |

Electrical components list for YFMD based on 380V/50HZ/3PHASE:

1. circuit breaker DZ47-60C40 C16: 2pcs

2. Frequency converter 3φ 380v 2.2kw: 1pc

3. Power S-100-24V: 1pc

4. Touch screen Model LEVI430T: 1pc

5. Small circuit breaker 1 C1X1610: 4pcs

6. Small circuit breaker 2 C1R3210: 1pc

7. Button switch IBZ.BZ101/2 C: 8pcs

8. Servo motor BcmAc30404PB: 1pc

9. Servo amplifier ASD-A0421-AB: 1pc

10. Solid state relay RJGX-3D4860: 1pc

11. PLC: 1pc

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: Africa,Americas,Asia,Emerging Markets,Europe,European Union,G20,Middle East,Oceania

- Founded Year: 2007

- Address: 2F208, NO.161 SANGUANDIANXIANG,XINHE STREET

- Contact: Mancy Mao