Plastic Film Extrusion Mould

Specifications

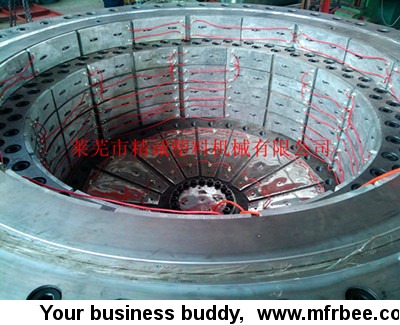

Plastic Film Extrusion Mould

This mould is designed following most advanced design idea in the world for large co-extrusion moulds, with the angle between runner and mould axis as 15 degrees. It adopts great-circle arc for any transition at turning or reducing places of the runner, thus leaving no death corner and keeping flow rate the same at each layer, and without eddy or cross-layer, leading to the rapid and fluent melt flow and reducing the possibility of melt fracture to the greatest extent.

This design helps reduce pressure within the head of machine and efficiently improves the extrusion output, which guarantees the products with good outlook, high quality and remarkable energy-saving effect. The practice shows that by adopting inclined-hole spiral runner technology, over 30 percentage of energy can be saved in than that of traditional mould.

By adopting new spiral runner and setting enough cushion space with proper design, the thickness of film is dramatically improved while the fusion line is eliminated.

Mould finishing shall be completed by high-precision CNC vertical lathe and CNC milling machine, which can perfectly meet all design requirements and enable the designers to manufacture the optimal blow-film mould by means of computer technology.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Middle East

- Founded Year: 1995

- Address: Lvhuayuan Industrial Park, Laiwu City, Shandong Province, China

- Contact: Ventura Meng