Ore flotation separation equipments

Product Quick Detail

- FOB Price

- USD $5,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- 20'container

- Delivery

- 15 Days

Specifications

Flotation process

The theoretical basis of variousflotation processes i

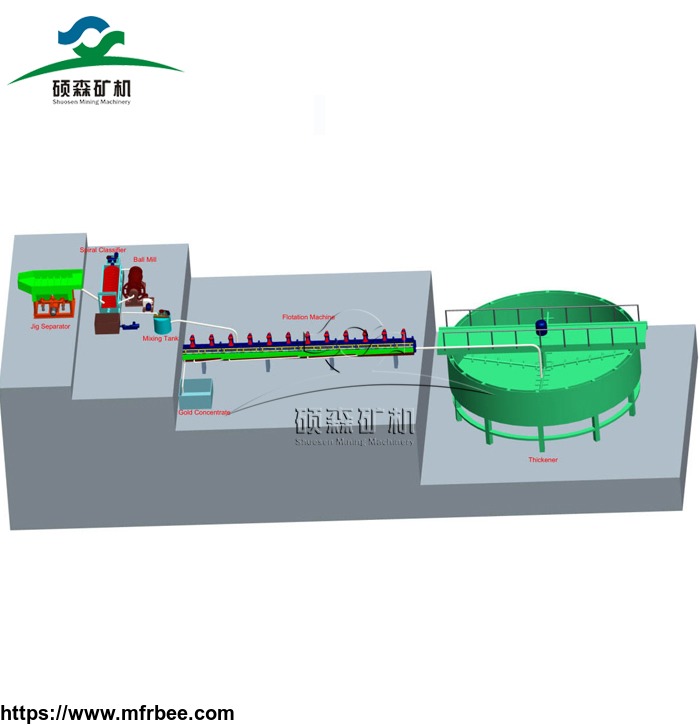

Flotation process equipments

Flotation process by jaw crusher, ball mill, classifier, magnetic separator, flotation machine, concentrator and dryer and other main equipment, with ore feeder, hoist, conveyor, vibrating screen

can form a complete ore processing line.The production line has the advantages of high efficiency, low energy, high processing capacity, economical and reasonable.

Grinding fineness test

The recovery rate of lead and zinc increased significantly with the improvement of grinding fineness. When the grinding fineness reached -0.074mm and 95%, the recovery rate of lead and zinc almost

reached the maximum at the same time.Continue to improve the fineness of grinding products, lead, zinc recovery began to decline slightly.Therefore, the appropriate grinding fineness of the

lead-zinc ore is -0.074mm, accounting for 95%.

Flotation condition test: the flotation condition test of galena ore includes Na2CO3 dosage test and butyl yellow drug dosage test, the flotation condition test of white lead ore includes Na2S

dosage test and butyl yellow drug dosage test, and the flotation condition test of heteropolar ore includes Na2S dosage test and phenylthiophenol dosage test.

Closed-circuit test

For the lead and zinc ores which are easy to grind and pulverize and have fine grain size, the floatability of the same mineral can be effectively reduced and the separation index can be improved

by using the graded sulfide flotation process and the difference of floatability of the same mineral.While Na2S sulfide white lead ore, a small number of heteropolar ore with good activity and

difficult to be inhibited by zinc sulfate and sodium sulfite are also sulfide, and thus float up with white lead ore, resulting in white lead concentrate containing up to 19.10% zinc.

If you want to know more about our equipments details,please contact us

www.shuosencrusher.com

sarahzzdshj@gmail.com

sarah@shuosencrusher.com

- Country: China (Mainland)

- Business Type: jaw crusher,impact crusher,cone crusher,ball mill, raymond mill, ore separator, rotary dryer, rotary kiln...etc

- Founded Year: 2015

- Address: JinQiao Economic Development Zone Shanghai China

- Contact: sarah niu