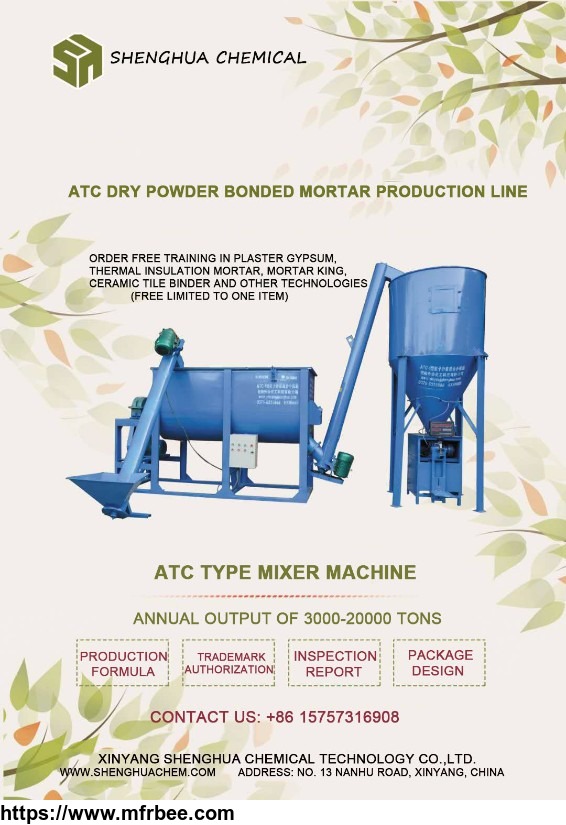

dry powder mortar mixer machine

Specifications

The production line containsfeed-mixing-storage-metering-packaging. widelyused in the production of various dry powder mortar, such as masonry mortar, adhesive mortar, crack resistant mortar, mortar king, inside and outside wall putty powder, plastering gypsum. ceramic tile adhesive, sealing agent and dry powder chemical materials mixing.

Characters:

1.Automatic, reasonable design of equipment, excellent performance, simple operation, low maintenance cost, effective production, labor saving and lower production

cost.

2. The mortar with fiber ingredients, it can effectively solve the problem of fiber dispersion in polymer dry mortar. Its is stable, high efficiency, mixing uniform, no dead angle.

3. It is less investment, quick effect, small footprint and simple operation. 2-4 people can operate, and the daily output (8 hours) is 5-16 tons.

4. It is reasonable price, high performance, and low maintenance cost. It has helped many customers successfully occupy the building materials market.

- Country: China (Mainland)

- Founded Year: 1988

- Address: No. 13 nanhu road

- Contact: Sun Jenny