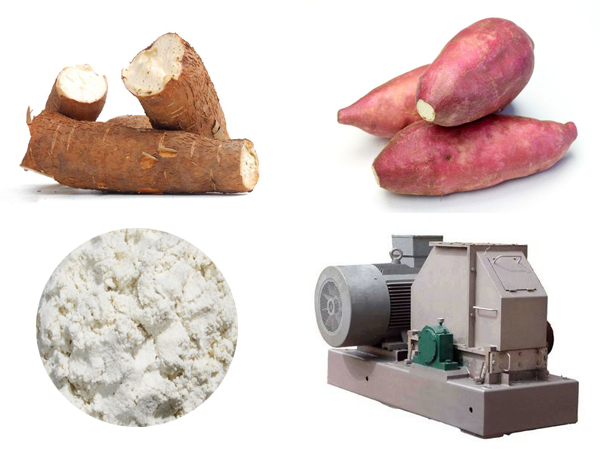

Cassava flour processing machinery

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

The cassava flour production equipment play an indispensable role in improving the economic value of cassava, especially compared with the previous cassava processing products, the newly designed cassava flour production equipment produced by Henan SIDA Mechanical Equipment Company now greatly improve the efficiency and value in process of cassava.

Cassava flour production Workflow:

Cassava flour processing equipment

First, cleaning and washing.

The purpose of the step is to remove sand and soil. Dry sieve can easily remove the soil and small stones by rotating at high speed without water. Paddle washing machine is able to handle the silt, gravel and outer peel of cassava. In addition, the dry sieve and paddle washing machine of cassava flour production in Nigeria can facilitate the work of the next process.

Second, peeling.

Cassava peeling machine has beautiful appearance and convenient operation. The peeling machine uses the pressure of the wind or water pump of the high pressure fan to produce the strong stirring movement of the water, making the material roll in the water, and combine the hair roll and the high pressure spray to achieve the special effect of peeling.

Third, crushing.

Cassava crushing equipment

Cassava flour hammer crusher is a device which use high speed rotating knife to break raw material into mush. The purpose of the crushing section is to ensure that the grinder operates normally. Some factories do not have broken processes, then the load of the crusher will be increased and the service life of the machine will be reduced. The hammer crusher is one of the hot selling machine of cassava flour production in Nigeria.

Fourth, filtering.

Plate and frame filter press is sealed by cardboard or filter material. It is a stainless steel plate and frame precision filter (also known as stainless steel cardboard filter). The filtering device of cassava flour production in Nigeria is for solid and liquid separation.

Fifth, flash drying.

After filtering and heating, the air enters the air distributor at the top of the dryer, and the hot air spirals evenly into the drying chamber. The high speed centrifugal atomizer of the top of the material of the tower is made into very fine mist droplets, which are in contact with the hot air, and can be dried in a very short time as the finished product. The finished product is continuously discharged from the bottom of the drying tower and cyclone separator, and the exhaust gas is drained away by the fan. So flash drying is a very ideal process of cassava flour production in Nigeria.

The cassava flour processing plant design (click to see the video) is suitable for medium and above scale flour processing manufacturers and customers. The process is automated from the process of cleaning, crushing, extracting, fine filtration, sand removal, concentration, refining, dehydration, drying and so on. Only taking ten minutes from raw materials to finished products because the production cycle is short. It effectively avoids the two pollution of the material exposed to air for a long time, such as oxidation browning and dust and microorganism, therefore the production efficiency and product quality will be improved.

- Country: China (Mainland)

- Business Type: 选择一个

- Market:

- Founded Year:1994

- Address:

- Contact:zhang xiansheng

Other products from Kaifeng sida agricultural products equipment co. LTD

Relate products of Cassava flour processing machinery

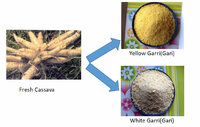

Features of Garri Processing Machinery Cassava Garri(Gari) Process Description and Flowchart: Garri is a fermented and gelatinized dry coarse flour, very popular in West Africa and a staple food in Nigeria, Ghana, Benin, and Togo. Its ability to store well and its acceptance as ...

Cassava Garri(Gari) Process Description and Flowchart: Garri is a fermented and gelatinized dry coarse flour, very popular in West Africa and a staple food in Nigeria, Ghana, Benin, and Togo. Its ability to store well and its acceptance as a \"convenience food\" is responsible ...

Features of Cassava Flour Milling Machine Processing Capacity: 400-500kgs/hour Application Scope: Milling the coarse powder into fine powder Product Introduction: Cassava milling machine, cassava miller for cassava flour and garri processing Product Description of Cassava ...