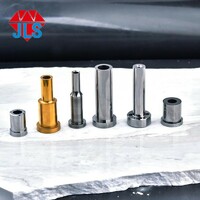

Pilot punches Button dies Precision Wear Parts

Product Quick Detail

- FOB Price

- USD $30.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China(Mainland)

- Material

- Tungsten Carbide /HSS

- Hardness Of Carbide

- 88-92HRA

- Carbide Grades

- WF20,WF30,KG7

- Trade Term

- EXW

- Payment Term

- T/T

- Customized According To Drawings

- Yes

- Packaging

- Customized

- Delivery

- 15 Days

Specifications

Pilot punches Button dies Precision Wear Parts

Carbide Mold Components – Die Punch

We customize die punch for customers , JLS is highly capable of producing precision carbide punch, buttons and bushings, ejector pin, die punches, carbide mold components according to your specific CAD drawing. Our certified raw material is imported from reputable companies CB-CERATIZIT, Kennametal, or other specified. Tungsten carbide is of super hardness, wear&corrosion resistance, corrosion resistance. The increased life of Super-hard tungsten carbide can offer greater productivity through improved performance and reduced downtime. Our products reach extremely close tolerances up to 0.001mm through continuous efforts over past years. Moreover, inner hole surface and outside surface can be processed with mirror surface grinding. Surface roughness can be up to 0.2a. TiN, TiCN, TiALN coating and PG grinding can be processed with tungsten carbide. fine polishing before coating and after coating is available.

How to make a deal with us?

1.Send us design drawing first

2.Check design drawing

3.Make a quotation

4.Quotation acceptance

5.Production&quality inspection

6.Delivery and shipping

Application

JLS wear components are widely serving for metal stamping industry, custom metal fabrication, injection mold industry,plastic mold/die makers, metal mold/die makers, tool and die maker, tool design& die making industries.

Why JLS?

Prompt Response

Competitive Prices

Most Quick&Consistent Delivery

Value-added Services

Material Control & Quality Inspection

JLS purchase tungsten carbide rods from reputable companies with material proof provided. You can check the material proof sheet on this website or ask our sales representatives to send latest versions. 100% INSPECTION is conducted to make sure every piece of products is perfect with flawless surfaces when delivery to customers. Our inspection facilities include Easson profile projector, Digimicro stand, MMD100B, slide calliper rule etc.

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: European Union,Asia,Americas

- Founded Year: 2000

- Address: No.468, Wushiling Third Zone, Yangwu Village, Dalang, Dongguan, China

- Contact: Abby Zhang