High fructose rice syrup production machine

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

In the traditional process of fructose syrup production line , it will need process rice starch from corn first,then use the rice starch to produce fructose syrup . But now our company has the new technology, our company fructose syrup processing plant can produce the fructose syrup from broken rice dirctly , it doesn't need to produce the starch first .

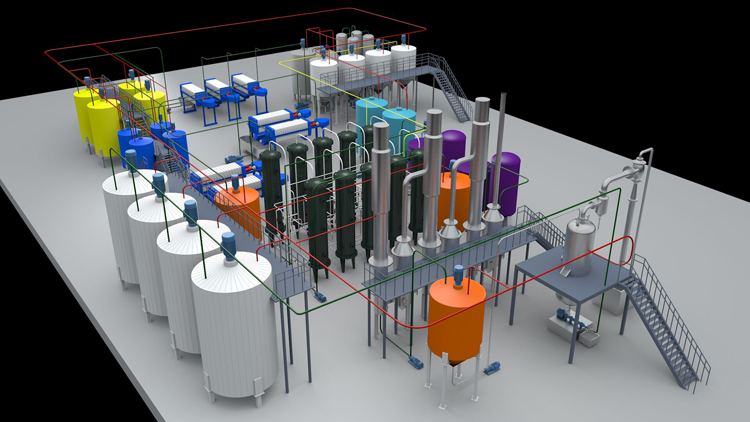

High fructose rice syrup production line

The production process of high fructose rice syrup production line as below :

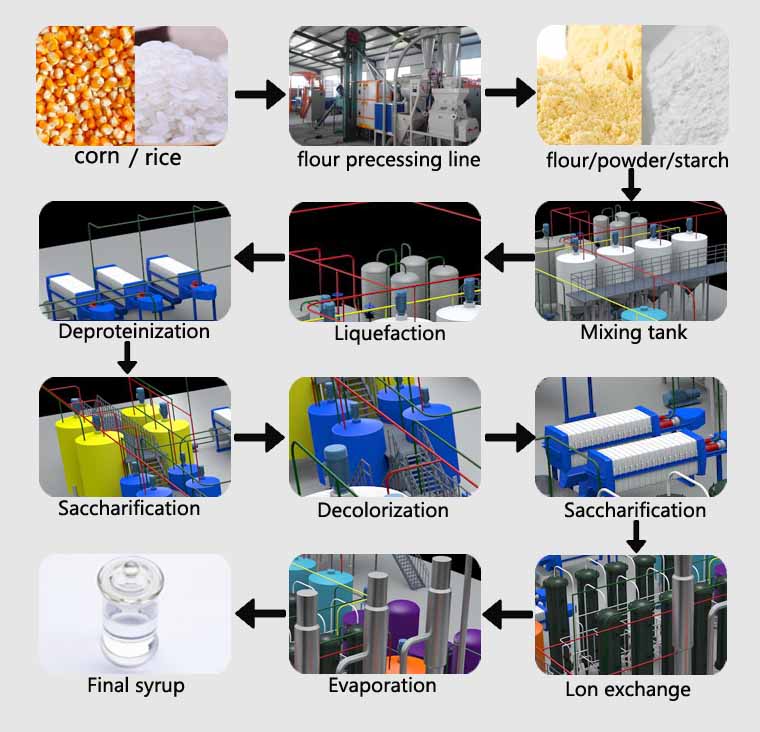

1. Rice powder making process in fructose syrup production line

Produce rice powder from broken rice with dry milling method , after remove the impurity from the broken rice , the clean broken rice will be milled into powder . After milling and sieving for some times to get the quality rice powder for making the rice syrup.

2. Rice power slurry making process in fructose syrup production line

Mixing the rice powder and water to get the right density slurry. Then add the amylase and keep on the temperature for particular time to make rice powder absorbing enough water .

3. Liquefaction process in fructose syrup production line

The liquefaction process is convert the starch which contented inside of the rice powder into liquid dextrin. The material will be sprayed at high temperature by jet cooker . With the aid of amylase and steam , the starch will be converted into liquid dextrin quickly.

4. Deproteinization process in fructose syrup production line

The deproteinization process is separate the rice protein and other solid impurity from liquid dextrin by filter press. The liquid dextrin will be pumped to next process, the corn protein will be left for sale. The by product rice protein ( feed grade) is top grade protein additives for making animal feed .

5. Saccharification process in fructose syrup production line

The saccharification process is convert the liquid dextrin into required DE value glucose syrup with the aid of gluco-amylase in the tank . This process should be run under specific temperature for some hours . For making high DE glucose syrup , it will need more longer time .

6. Decolorization process for glucose syrup in fructose syrup production line

The decolorization process is removing the color of the glucose syrup by activated carbon. The glucose syrup which reached required DE will be pumped from saccharification tank into the decolorization tank , mixed with activated carbon at proper temperature .

7.Decarburization process for glucose syrup in fructose syrup production line

The decarburization process is separating the activated carbon from the glucose syrup by filter press to get clear glucose syrup.

The glucose syrup will flow into the slot and the transfer tank for next step. The activated carbon will be left.

8. Ion exchange process for glucose syrup in fructose syrup production line

The Ion exchange process is using the resin to remove the tiny foreign items and bad odor to get high quality pure glucose syrup.

The resin need regeneration by acid and alkali washing after working for some days.

9. Evaporation process for glucose syrup in fructose syrup production line

The evaporation process is evaporate the water inside the glucose syrup to increase the DS of glucose syrup to the requirement (45%) before isomerisation.

10. Isomerism process in fructose syrup production line

The isomerism process is convert the glucose syrup to fructose syrup with the aid of isomerase. The glucose is converted into with 42% content of fructose syrup.

11. Decolorization process for fructose syrup in fructose syrup production line

The decolorization process is removing the color of the fructose syrup by activated carbon. The fructose syrup will be pumped into the decolorization tank , mixed with activated carbon at proper temperature .

12. Decarburization process for fructose syrup in fructose syrup production line

The decarburization process is separating the activated carbon from the fructose syrup by filter press to get clear fructose syrup.

13. Ion exchange process for fructose syrup in fructose syrup production line

The Ion exchange process is using the resin to remove the tiny foreign items and bad odor to get high quality pure fructose syrup.

The resin need regeneration by acid and alkali washing after working for some days

Flowchart of High fructose rice syrup

14. Evaporation process for fructose syrup in fructose syrup production line

The evaporation process is evaporate the water inside the fructose syrup to increase the DS of fructose syrup to the requirement ( DS around 71%)..

15. Final product storage in fructose syrup production line

The fructose syrup which reach the required DS in the evaporation process will be pumped into final product storage tanks for storage.

The final product tank can keep the fructose syrup purity before transportation.

- Country: China (Mainland)

- Business Type: 选择一个

- Market:

- Founded Year:1994

- Address:

- Contact:zhang xiansheng

Other products from Kaifeng sida agricultural products equipment co. LTD

Relate products of High fructose rice syrup production machine

China glucose syrup production machine/ glucose fructose processing equipment Glucose syrup production machine is a industry production, usually requests large capacity.kaifeng sida is a professional glucose syrup production machine manufacturer, and can offer glucose syrup ...

High fructose corn syrup production plant / high fructose syrup production line kaifeng sida has a professional starch syrup technical team, can provide customers with maltose syrup, fructose syrup, glucose syrup production technology and engineering design, has the ...

The raw material for high fructose corn syrup production is the raw grains which contain abundant starch, so actually, the material used in the high fructose corn syrup production plant is the starch, all kinds of starch are suitable. High fructose corn syrup production process ...