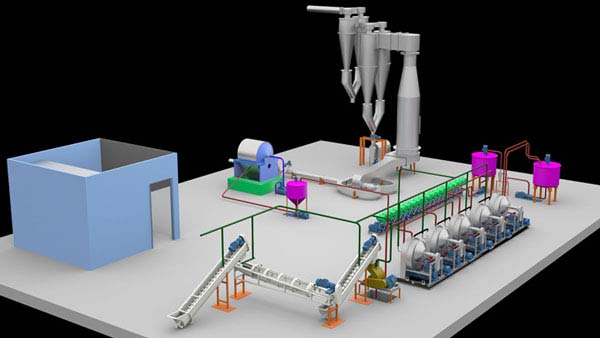

yam flour(starch) processing machine

Specifications

Advantage of yam starch (flour) processing line

1. Good performance; high efficiency

2. Stainless steel construction

3. High level machining, equipment manufacturing excellence

4. Good supervision, commissioning and assistance

5. Low maintenance, simple operation

6. Pumps, motors, piping and instrumentation installed on the same integrated frame

7. Closed system, easy to clean and CIP

8. Fully communicate with the user to provide the best engineering design and facility layout

yam Starch Production Process:

Fresh yam → yam washing → Peeling → Grinding → Centrifuge sieve → Desanding → Hydrocyclone → Dewatering → Drying

The description of yam flour processing line:

yam cleaning and peeling → yam grinding → screening and filtering → sifting → drying → Fine milling → High quality yam flour packing.

yam flour production plant introduction

Main process of yam starch production line:

1. yam peeling and washing section for yam starch production line:The purpose of this unit is to get rid of sandstone, clay of yam, and to deposit cleaned yam in the yam temporary hopper.

yam cleaning and peeling machine

2. Crushing section during the yam starch production line: The crushing unit is the most important step for extracting yam starch. Highly-efficient crushing machine will release the starch in yam at most.

Yam crushing machine

3. Centrifugal extracting section during the yam starch production line:The yam starch slurry and residue will be separated from the starch milk.

Starch refining hydrocyclone

4. Desanding section during the yam starch production line: Removing the sand in the starch slurry.

5. Concentration and refining section during the yam starch production line:Working through the hydroclone, there are 2 steps, including concentration and refining so that we can get purier starch slurry.

6. Vacuum dewatering section during the yam starch production line: The starch slurry is pumped into inlet tank of vacuum dewatering machine. Then the vacuum rotary drum will adsorb the starch on the drum surface and the filtrate is transferred out of the system by filtrate pump. The filter cake on the drum will be peeled off by peeler and then transferred to the air dryer by screw conveyor.

7. Air-stream drying section during the y starch yam production line: After dewatering process, the air dryer will dry the starch to the required moisture of the commercial starch.

yam flour production plant introduction :

To produce high qualtiy yamflour, The fresh roots must be healthy without rot and well handled from farm. The roots should be processed within 24 hours after harvesting.

1、yam washing and peeling: Before peeling , the raw yam will be washed first to remove the sand , mud and other impuirty. Peeling is essnetial work for making high quality yam flour.After washing ,the yam will peeled by he yam peeling machine.

2、Wet milling: The peeled yam will be trasnport into clean stainless steel yam milling machine to obtain uniformly smooth mash.The yam mash must be uniformly smooth without lumps. The smoothness of the mash determines the quality, yield and market value of the finished yam flour.

3、Dewatering: For commerical automatic production, we use the press filter to press the yam mash for removing the water as much as possible.

4、Cake breaking : After press, the yam mash will be pressed to yam cake. The yam cake will be transport into milling machine for breaking into wet powder form.

5、Drying and sieving: The special designed yam flour drying machine will dry the wet yam in few seconds. After drying ,the moisture level of yam flour can meet national regulatory standards. Then the yam flour will be sievied to separate the big particle flour.

starch drying machine

yam flour(starch) processing machine

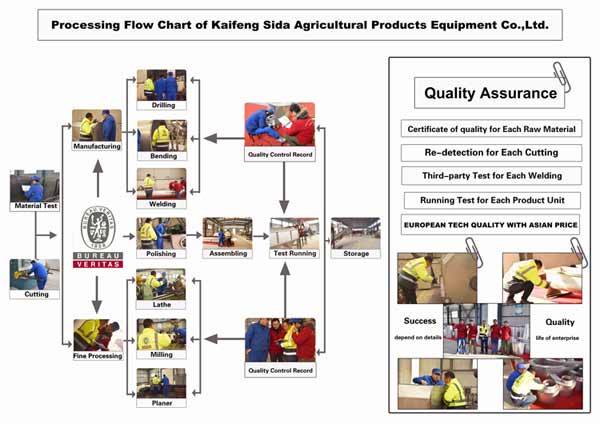

Our processing machines are fully tested by BVI Bureau Veritas in France and 100% of the processing technology is up to standard.

Bureau Veritas is the industry promoter of testing, inspection and certification services. By providing quality services, BVI helps customers cope with increasing challenges in terms of quality, health, safety, environmental protection and social responsibility.

As a trusted business partner, Biwei provides innovative solutions that not only help customers meet the requirements of regulations and standards, but also reduce risks, improve performance and promote their sustainable development.

Some project cases

We set up yam processing machines in Africa

Around our machines all over the world have completed project can visit, our machines with the third party inspection agency France Bureau Veritas and 100% high quality qualified, machine quality, advanced technology, perfect service quality, Now order the machine and we will give you the best price.

Our completed projects in Malaysia、 Europe、America 、Africa Nigeria, Tanzania, you can be visited.If you have cassava、 potatoes、 sweet potato、 corn 、plantain 、yam processing starch and flour processing, corn&rice syrup processing machine and other problems,Please leave a message under the website,Or send email:sida@cnstarchmachine.com, or consult our online customer service. We will answer your questions immediately. Welcome to the consultation.The Company manager go to Nigeria or your country, you can to talk with manager.

Strict quality inspection system, mature management and after-sale service for your technical support

Manufacturers of yam starch production machine,yam starch processing machinery for sale,yam starch making equipment,yam starch plant,supply technical support of yam starch processing line.

Add: Huanglong garden in Kaifeng Economic Development Zone, Henan

Phone /whatsapp: +86 18438491113

Email : sida@cnstarchmachine.com

Tel : +86 371--26630769

- Country: China (Mainland)

- Business Type: 选择一个

- Founded Year: 1994

- Contact: zhang xiansheng