Starch Processing Line

Specifications

complete set sweetpotato starch processing line

Advantages of our sweet potato starch processing machinery:

1.One production line can transfer cassava, potato and sweet potato to starch directly. It can save a lot of cost.

2.Low energy consumption, high capacity, fine particles, easy installation, stable operation and friendly maintenance.

3.All stainless steel 304 cover meets to GMP standard.

4.After-sales Service Provided Engineers available to service machinery overseas for one year.

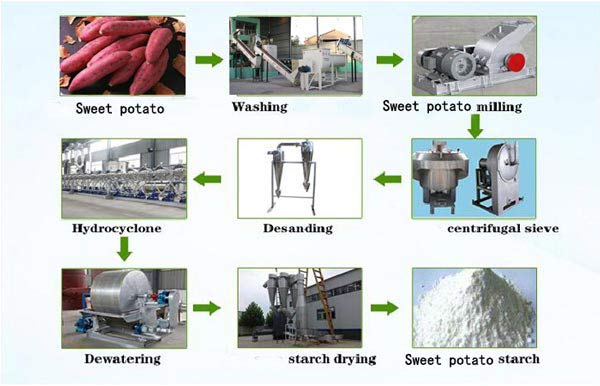

sweet potato starch production machine flow process chart

Introduction of sweet potato starch processing machinery :

Sweet potato production machinery adopts wet processing for starch production, do not add any additives in the whole production line. Our starch production line is a line with mature technology, advanced equipment, reasonable design. The whole production line machines includes: Feeding Machine; Washing Machine; Washing Peeler; Grinder; Dewatering Machine; Flash Dryer; Milling; Sieving Machine; Packaging Machine for Flour.

1. Cleaning and washing equipment: After the sweet potatoes are transported to the workshop, the cleaning and washing work should be carried out in order to avoid affecting the normal operation of the processing section and product quality. In the cleaning process, the damage of potatoes should be reduced to avoid unnecessary loss of starch. sida Company use dry sieve and rotary washing machine for the cleaning and washing process which can meet the technical requirements of high efficiency and low consumption.

potato cleaning and peeling machine

2. Grinding machine: Grinding machine is a key sweet potato starch processing equipment. It is mainly used to grind sweet potato into potato slurry so as to release potato starch from potato. sida Company has developed a high efficient grinding machine on the basis of absorbing foreign advanced technology. The equipment is called rasper which has the characteristics of high power, high speed, fine material grinding, high starch extraction rate and high grinding coefficient.

sweet potato crushing machine(cassava grating machine)

3. sweet Potato starch separating machine: The separation of sweet potato slurry in the process of potato starch processing are generally carried out by multistage centrifugal sieve. This sweet potato starch processing equipment can be used in multiple units, with the advantages of large capacity, small power, stable operation, easy installation and so on. It can effectively remove the fibers out of starch slurry. And fine fiber sieve is also used for separating whose main purpose is to further remove fine fibers from starch slurry.

4. sweet Potato starch concentration and refining machine: sweet Potato starch concentration and refining depend on starch cyclone, which is divided into concentrated cyclone and refining cyclone. After separating, the starch slurry first passes through the concentrated cyclone, and the bottom flow enters the washing and refining cyclone, and after multi-stage hydrocyclone process, the starch meets the quality requirements of the product. The equipment is equipped with a complete set of automatic control system and adopts high-quality swirl tube and optimized drainage scheme which is an ideal choice for potato starch processing equipment.

Starch refining hydrocyclone

5. sweet Potato starch dewatering machine: The vacuum filter is adopted for starch slurry dewatering. The equipment also has washing effect in the dewatering process. It has the advantages of low energy consumption, good dewatering effect, convenient installation and stable operation. Automatic feeding, automatic dewatering and automatic cleaning can be realized. It is the most ideal starch dewatering equipment.

6. sweet Potato starch drying and packing machine: Flash dryer is the widely used sweet potato starch processing equipment for drying. The negative pressure flash dryer uses the high speed flow of hot air to suspend the wet starch and dry the wet starch in the process of air flows. It has the characteristics of high heat transfer coefficient, large heat transfer area and short drying time. Then the sweet potato starch is packed by semi-automatic packing machine for marketing.

sweet potato starch drying machine

Strict quality inspection system, mature management and after-sale service for your technical support

Add : Huanglong garden in Kaifeng Economic Development Zone, Henan

Phone/whatsapp : +86 18438491113

Email : sida@cnstarchmachine.com

- Country: China (Mainland)

- Business Type: 选择一个

- Founded Year: 1994

- Contact: zhang xiansheng