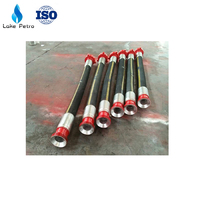

High-quality API Sucker Rod Blowout Preventer

Product Quick Detail

- FOB Price

- USD $200.00 / Piece

- Place Of Origin

- Shandong, China (Mainland)

- Warranty

- one year

- Condition

- New

- Material

- Carbon Steel

- Machine Type

- Drilling Tool

- Connection

- Thread or Flange

- Supply Ability

- 100 pieces / per month

- Minimum Order

- 1

- After-Sales Service Provide

- No overseas service provided

- Certification

- API

- Color

- Required

- Processing Type

- Forging

- Use

- Well Drilling

- Processing Time

- 30 days

- Payment Terms

- T / T; L / C; Western Union

- Packaging

- Standard Export Package

- Delivery

- China Main Port

Specifications

Rod BOP to prevent the leakage of oil and gas in the recovery operation control device, can guarantee the well- flushing, sand washing, fracturing downhole operation smoothly. By changing different valve core, and can meet the needs of all kinds of rod seal. Product design reasonable, simple structure, convenient operation, raliable sealing, long service life and is one of indispensable tools in oil field work.

2. Main Technical Parameters:

(1) . The working pressure: 1500 psi; 2000 psi; 3000 psi; 5000 psi.

(2) . Suitable for sucker rod specifications: 5/8”~1 1/2”.

(3) . The upper and bottom nipple: API tubing thread: 2 3/8” NU; 2 7/8” NU; 3 1/2” NU; 4” NU; 4 1/2” NU; 2 3/8” EU; 2 7/8” EU; 3 1/2” EU; 4” EU; 4 1/2” EU.

3. FAQ:

Why you need to choose Lake Petro?

As a professional oil and gas service company, Lake Petro has many good experience in selling and serves for the oilfield industries for years. Quality is the culture of the company, we provide API and BV certified products for customer.

Can you make us the best quality products as well as a good price?

Yes,we can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us yourmoney will be safe.

What is special compare with other companies?

First, we provide the quality products, with BV and API certified; At the same time, we provide our customer with the best service after sale, any time any where.

- Country: China (Mainland)

- Business Type: Oil Field Equipment

- Market:选择一个

- Founded Year:2011

- Address:Huanghe Road,Dongying City,Shandong Province, China.

- Contact:Gideon Peng

Other products from Dongyng Lake Petroleum Technology Co.,Ltd

Relate products of High-quality API Sucker Rod Blowout Preventer

1. Main Technical Parameters: 2. Product Description: Pumping pump is a common downhole device driven by a pumping unit to pump crude oil from the well to the ground. General pumping pump is mainly composed of four parts: barrel, suction valve, plunger, and exclusion valve. ...

1. Main Technical Parameters: 2. Product Description: Sucker rod guide is a downhole tool for preventing eccentric wear of pumping wells, which is suitable for pumping wells with eccentric wear, especially for pumping wells with eccentric wear above the neutral point of sucker ...

1. Main Technical Parameters: 2. Product Description: Advanced thermal spraying technology is adopted to melt Ni alloy and other high wear-resisting materials on the blank surface of the collar after high temperature flame spraying, so as to reduce the friction coefficient ...