Cast Aluminum

Product Quick Detail

- Minimum Order

- 10

- FOB Price

- USD $2.00 / Piece

- Place Of Origin

- China

- Packaging

- custom

- Delivery

- 15 Days

Specifications

Quick Information

- Brand Name:KC

- Place of Origin:China

- :

Description

Cast aluminum

Our company deals in aluminum castings, including mechanical die-casting, automotive die-casting, guardrail aluminum, cast aluminum pump, export aluminum and so on.

The application of aluminium materials and aluminium alloys in aluminium die castings has good fluidity and plasticity, so it is possible to make all kinds of complex and difficult die castings. The castings cast with aluminium alloys and aluminium metals have high accuracy and surface finish, which greatly reduces the mechanical workload of castings, greatly reduces labor intensity, and saves power and metal materials.

Forming process of die-casting aluminium parts:

1.Annealing

2. Normalizing

3. Quenching

4. Tempering.

These four processes are called \"four fires\" in die casting. In the process of die casting, the relationship between quenching and tempering is very close, and both of them are indispensable.

The surface treatment methods of aluminium materials include:

1. anodizing treatment;

2. spraying and plastic spraying treatment;

3. drawing treatment;

4. dyeing treatment.

Price

- Delivery Port :Tianjin

Packaging & Delivery

- Packing :custom

- Delivery Lead Time :7 days

- Supply Ability :1000kg/week

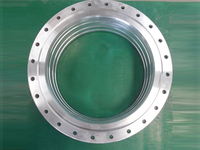

Product Image

- 1

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Founded Year: 2014

- Address: No. 58 Fangbei Rd, Shijiazhuang 050011, Hebei province, China

- Contact: LI Meici