API Downhole Drilling Motor / Mud Motor

Product Quick Detail

- FOB Price

- USD $10,000.00 / Piece

- Place Of Origin

- Shandong, China (Mainland)

- Warranty

- one year

- Condition

- New

- Model

- Downhole Drilling Motor

- Processing Type

- Casting

- Use

- Well Drilling

- Supply Ability

- 1000 pieces / per year

- Minimum Order

- 1

- After-Sales Service Provide

- No overseas service provided

- Certification

- API

- Color

- Required

- Material

- Carbon Steel

- Machine Type

- Drilling Tool

- Processing Time

- 30 days

- Payment Terms

- T / T; L / C; Western Union

- Packaging

- Standard Export Package

- Delivery

- China Main Port

Specifications

The Lake Drilling Motor is a powerful and reliable positive displacement motor. The motor generates an optimum balance of rotational speed and high torque to drive a variety of drill bits at speeds that maximize tool life and performance. Lake Motors offers a choice of flow rates, speeds and torque to match a wide range of operation parameters. Lake Motors are used in applications such as straight hole drilling, directional (steerable) drilling, horizontal drilling, hole opening and re-entry (work over).

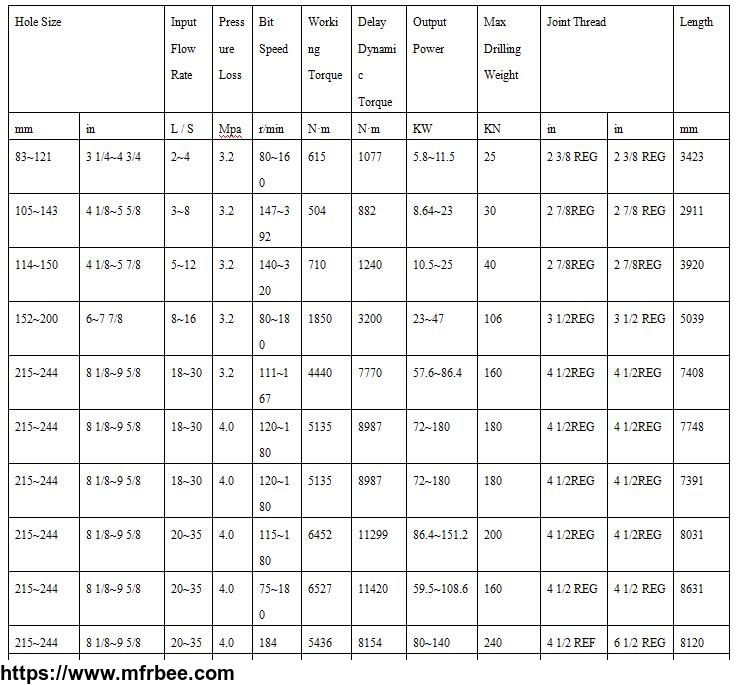

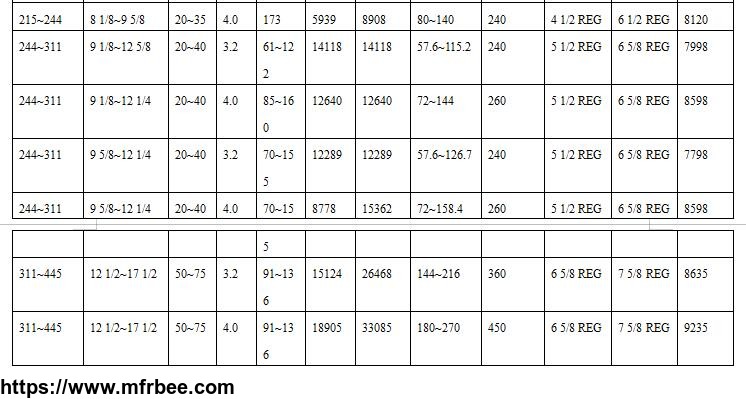

2. Main Technical Parameters:

3. Features:

(1). Increased rate of penetration.

(2). Better hole deviation control.

(3). Reduction in drill string failure rate.

(4). Reduction on wear and tear of the swivel, Kelly, and rotary drives.

(5). Reduction in fuel cost, since compared to rotary drilling, less energy is required to power a downhole motor.

(6). Big torque, high effective, wide flow rate range, running stable and long using time.

(7). API spec, standard.

4. FAQ:

Why you need to choose Lake Petro?

As a professional oil and gas service company, Lake Petro has many good experience in selling and serves for the oilfield industries for years. Quality is the culture of the company, we provide API and BV certified products for customer.

Can you make us the best quality products as well as a good price?

Yes,we can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us yourmoney will be safe.

What is special compare with other companies?

First, we provide the quality products, with BV and API certified; At the same time, we provide our customer with the best service after sale, any time any where.

- Country: China (Mainland)

- Business Type: Oil Field Equipment

- Market:选择一个

- Founded Year:2011

- Address:Huanghe Road,Dongying City,Shandong Province, China.

- Contact:Gideon Peng

Other products from Dongyng Lake Petroleum Technology Co.,Ltd

Relate products of API Downhole Drilling Motor / Mud Motor

Product Description Drilling Motoris a kind of downhole power frilling tools by mud. The mud output by the mud pump, will enter the motor through the bypass valve, and a certain pressure difference will be formed at the inlet and outlet of motor, to push the rotor of motor to ...

1. ADVANTAGES OF DOWNHOLE MOTOR Increased rate of penetration. Better hole deviation control. Reduction in drill string failure rate. Reduction in wear and tear of the swivel, Kelly, and rotary drives. Reduction in fuel cost, since compared to rotary drilling, less energy is ...