API Well Drilling Stabilizers Near Bit Stabilizer with Back-reamer

Product Quick Detail

- FOB Price

- USD $2,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Shandong, China (Mainland)

- After-Sales Service Provide

- No overseas service provided

- Warranty

- one year

- Certification

- API

- Condition

- New

- Color

- Required

- Material

- Stainless Steel

- Processing Type

- Forging

- Machine Type

- Drilling Tool

- Use

- Well Drilling

- Processing Time

- 30 days

- Supply Ability

- 300 pieces / per year

- Payment Terms

- T / T; L / C; Western Union

- Packaging

- Standard Export Package

- Delivery

- China Main Port

Specifications

The stabilizer with backreaming is selecting the appropriate location and through special processing method to array few teeth as a cutting edge. In this way, this stabilizer can be played cutting when the process of drilling and pull out. During drilling process, forward and backward redressing can be played the role to repair and maintain the wall of well, making trajectory of borehole as far as possible, more often than not leading to drilling difficulty because of hole shrinkage, and so on, at the moment, the forward and backward redressing of this stabilizer can be played cutting, to eliminate hole shrinkage phenomenon, thus saving time and costs for drilling.

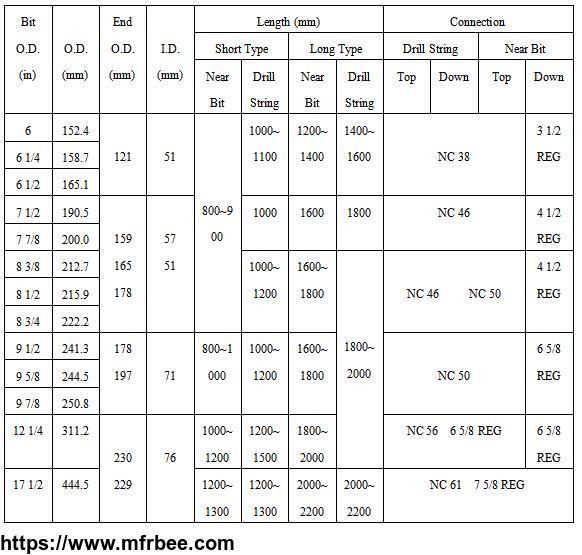

2. Main Technical Parameters:

3. Features:

(1). Sizes and configurations can be manufactured to operator’s requirements, including blade sizes, connections, and types of material.

(2). All stabilizers connections can be configured as box × box, as pin × box, or as the operator requires.

(3). Welded straight blade for drilling soft formations.

(4). Sleeve type allowing less equipment inventory in remote locations.

(5). Integral spiral blade allowing 3600 hole contact for use in hard rock formations.

(6). Nonmagnetic stabilizers for applications requiring magnetic isolation.

4. FAQ:

Why you need to choose Lake Petro?

As a professional oil and gas service company, Lake Petro has many good experience in selling and serves for the oilfield industries for years. Quality is the culture of the company, we provide API and BV certified products for customer.

Can you make us the best quality products as well as a good price?

Yes,we can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us yourmoney will be safe.

What is special compare with other companies?

First, we provide the quality products, with BV and API certified; At the same time, we provide our customer with the best service after sale, any time any where.

- Country: China (Mainland)

- Business Type: Oil Field Equipment

- Market: 选择一个

- Founded Year: 2011

- Address: Huanghe Road,Dongying City,Shandong Province, China.

- Contact: Gideon Peng