High-quality API Spec 6A Hydraulic FC Gate Valve

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Shandong, China (Mainland)

- After-Sales Service Provide

- No overseas service provided

- Warranty

- one year

- Certification

- API 6A

- Condition

- New

- Color

- Required

- Material

- Alloy Steel

- Processing Type

- Forging

- Machine Type

- Drilling Equipment

- Use

- Well Drilling

- Working Medium

- oil, nature gas, mud and gas containing, H2S, CO2

- Structure

- Gate

- Conncetion

- Flange, etc

- Pressure

- High / Medium / Low Pressure

- Power

- Manual

- Media

- Water, oil

- Temperature Of Media

- High / Medium / Low Temperature, Normal Temperature

- Application

- Well Drilling

- Port Size

- All sizes

- Processing Time

- 30 days

- Supply Ability

- 5000 pieces / per month

- Payment Terms

- T / T; L / C; Western Union

- Packaging

- Standard Export Package

- Delivery

- China Main Port

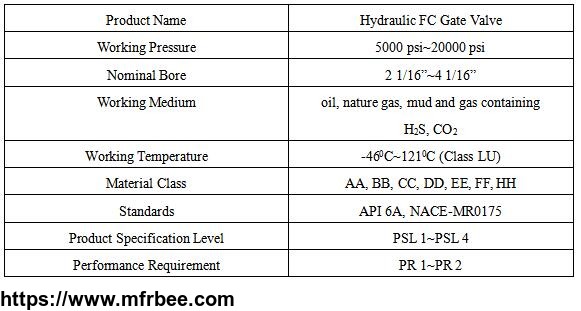

Specifications

Gate Valve is used to open or close the pipeline. According to the structure, the gate valves is distributed into rising or non-rising stem gate valve. According to the mode of operation, it is distributed into manual or hydraulic etc. The gate valve is used for drilling fluid manifold, choke manifold, kill manifold and Christmas tree etc.

FC valve:

(1). Full-bore design, effectively eliminate the pressure drop and eddy current, slow flow of solid particles in the valve.

(2). The unique sealing, make the switch torque greatly reduced.

(3). Between bonnet & body and gate & seat are adopt metal to metal seal.

(4). Between gate and seat are adopt metal to metal seal, surface spraying (heap) welding hard alloy, has good abrasion resistance, corrosion resistance.

(5). Seat ring is fixed with plate, keep well steady.

(6). Stem has back seal structure so as to replace seal ring of stem with pressure.

(7). There is seal grease injection valve on bonnet sided so as to repair seal grease, and provided seal and lubricate performance of gate and seat.

(8). It is match with all kind of pneumatic (hydraulic) actuator as customer’s requirements.

2. Main Technical Parameters:

3. Features:

(1). Sealing for body and cover is metal to metal seal, improve the sealing performance.

(2). Stem and cover designed with backseat sealing structure is easy to take pressure change valve stem packing.

(3). The body is made of high quality alloy steel steel forgings, no perforation design, safe and reliable.

(4). Sealing surface spray weld hard alloy, with corrosion resistance, resistance to erosion and wear resistance performance.

(5). Body pad ring groove can according to user’s requirement overlaying austenitic stainless steel, improve the corrosion resistant ability to enhance its service life.

(6). Use spring preload load in the disc and seat, completely realize two-way seal.

4. FAQ:

Why you need to choose Lake Petro?

As a professional oil and gas service company, Lake Petro has many good experience in selling and serves for the oilfield industries for years. Quality is the culture of the company, we provide API and BV certified products for customer.

Can you make us the best quality products as well as a good price?

Yes,we can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us yourmoney will be safe.

What is special compare with other companies?

First, we provide the quality products, with BV and API certified; At the same time, we provide our customer with the best service after sale, any time any where.

- Country: China (Mainland)

- Business Type: Oil Field Equipment

- Market: 选择一个

- Founded Year: 2011

- Address: Huanghe Road,Dongying City,Shandong Province, China.

- Contact: Gideon Peng