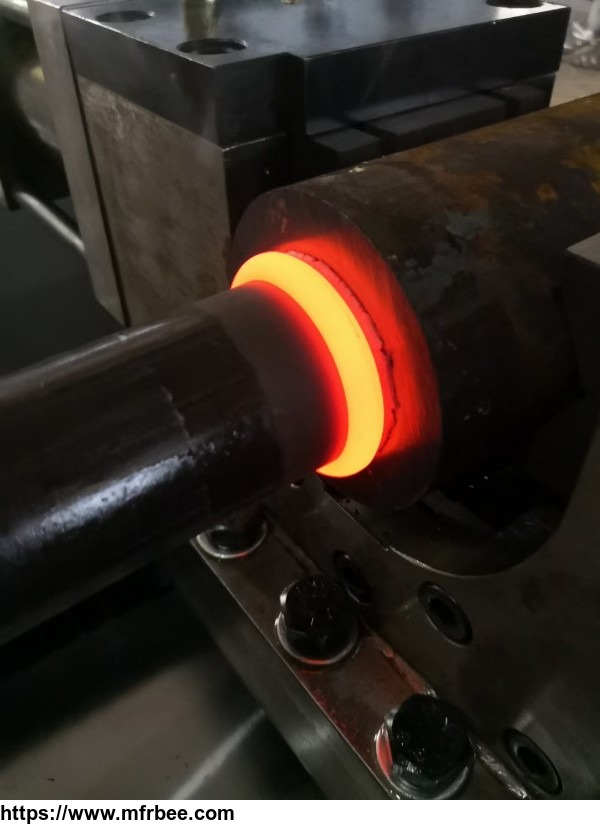

Drill pipe Friction Welding Machine

Specifications

MCH-120SJ FRICTION WELDING MACHINE

SHANGHAI SHENG CHUN MACHINERY CO.,LTD

TechnicalParameters Catalog

Technical parameters provider: ShanghaiSheng Chun Machinery Co., Ltd.

Welding material: SS--SS

Welding diameter: Ø42mm&Ø90------Ø65mm&Ø100mm.

Weldingjointarea range: Min:1385mm2(12-65)~Max:6358mm2(90-100),

Calculated according to theupsetting force of welding16KG/mm2, theupsetting force required for welding is220KN-1017KN.

It is recommended to use the MCH-120SJ type friction welding machine.

The maximumupsetting force is1200KN and the welding area is 1200mm2~7000mm2, which can fully meet the welding of this series.

This technical document contains the following:

Ⅰ. Main technical characteristics of MCH-120SJ type friction welding machine

Ⅲ.Configuration list of MCH-120SJ type friction welding machine

Ⅴ.Purchased parts list of MCH-120SJ type friction welding machine

Ⅵ.System menu of MCH-120SJ type friction welding machine

SHANGHAI SHENG CHUN MACHINERY CO.,LTD

Date:2018-8-7

Ⅰ. Main technical characteristics of MCH-120SJ type friction welding machine

MCH-120SJ (maximumupsetting force1200KN, servo monitor) type friction welding machine is Shanghai Sheng chun Machinery Co., Ltd. in 2012, self-developed new products.Own patented technology -servoSpindle drive system andservohydraulic control system. By servo spindle drive system, the spindle speed can reach up to 1000 r/ min, the current domestic production of 100 tons friction welding machine spindle speed substantially at 600 r/ min or less. As a result of high-speed welding, effective control of the thermal diffusion zone welding parts, so that the accuracy and stability of welding a reliable guarantee. Meanwhile spindle bearings lubricated with grease, to avoid the dirty lubricating oil due to the spindle bearing potential threat, and greatly improve the bearing life of the machine.Byservohydraulic controlling system enables allclosed-loop cylinders working, welding parts of the stability of a reliable guarantee.Meanwhile, the system uses the welding parameters storage function in the production process, we only need to call up the corresponding product specifications to automatically match the welding parameters, reducing the operator to adjust the parameters of the process. As a result of servo hydraulic system, greatly reducing the temperature of the hydraulic fluid, so that the machine can be more stable pressure and feed rate, which greatly reduces the hydraulic system to produce due to the instability caused by the quality of welding reject rate. The model with the same general type of friction welding compared to the power consumption can be reduced by more than 50%.

The main structure

The machine consists ofSpindle, slide, master cylinder, rotary fixture, moving the fixture, fixture composed of tanks,body, hydraulic system, electric control system, operator panel and other components.

n Machine body, Spindle box

Body andshaft box are made of welded steel material, tempered sandblasted.

Bed ribs arranged inside the body, so thick bed structure. Guide the use of heavy-duty roller linear guide deputy structure, so that the machine to obtain a high rigidity and long-term stability of precision. Reciprocating motion slide along the linear guide, induced by the magnetic displacement sensor detects the motion displacement of the closed-loop and set the amount of melted welding, weld length to ensure consistency.

Spindle power system uses servo motor drive system, it can be a variety of welding the welding speed depending on the diameter of the election.

n Clamp

Rotatingclamp with hydraulic clamping chuck, the chuck having a clamping force, easy to replace the product, holding high precision.

Mobileclamp using self-centering hydraulic clamp, a higher repeat accuracy.

Both fixture on the replacement of the product to adjust the amount of time than other products at home and abroad at present to 50% less.

n Hydraulic System

The hydraulic system uses our patented productfriction welding servo-hydraulic system, features include forward and back through the master cylinder control slide, the clamping fixture release. Pressure and flow measurement and control closed loop servo system, the parameters can be adjusted through the man-machine interface, and save multiple sets of welding parameters. The system has a less demanding on the oil, easy maintenance, and other advantages over more than 60% of power consumption and heat generation to reduce other domestic products.

n Automatic removal of welding flange function

According to user needs to install inside automatic car flanging and flanging punch function.

n Automatic loading and unloading function

According to user needs to install automatic loading and unloading functions.

- Country: China (Mainland)

- Business Type: Manufacturer for Friction Welding Machine

- Market: Africa,Americas,Asia,Emerging Markets,Europe,European Union,G20,Middle East,Oceania

- Founded Year: 2002

- Address: No.500 Xingfang Rd,Xingta Industrial park,Jinshan District,Shanghai,CHina

- Contact: Frank Xie