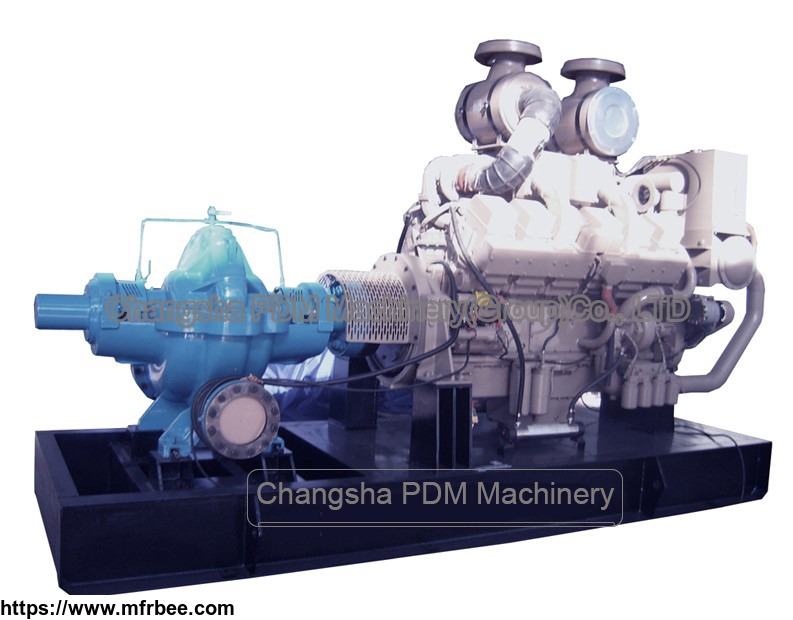

Diesel Split Case Centrifugal Pump Set

Specifications

Now we are the largest manufacturer for the split casing centrifugal pump and various pumps in China presently, especially the industrial big pump. Now we make pumps for ITT and Toshiba for OEM

manufacture. The biggested impeller for single stage can be up to 2.6m. The highest head can be up to 240m.

Technical advantage

With short gaps in the both ends of support, this type pump works stably with less noise and vibration. It can be risen speed operation to meet wider usage.

Being inlet and outlet located in the same center line, the pipelines arrangement looks simple and beautiful.

The rotor can be operated in reverse direction to avoid damage to the pumps from water hammer.

Unique design of high temperature, using middle support, thickening pump casing, seal cooling and oil lubrication bearing make this type pump suitable for working at 200C, especially for heat supply newtwork requirements.

This type pump case body can be vertically or horizontally installation acoording to different working condition, with mechanical seals or packing seals.

Wtih industrial designs to the shape of this type pump, the line of pump is clear and beautiful to in line with modern aesthetics.

Cost advantage

1. Using the advanced hydraulic model, the efficiency of this pump is 2%~3% higher than the same type pumps. The operating cost minimum.

2. The vacuum height of this type pump is risen 1-3 meter to reduce land construction investment and to extend the service life.

3. Using inport brand bearing, such as SKF, NSK and using various pump material make this type pump suitable for any site working condition and minimize the maintenance cost.

Maintenance advantage

1. With container type mechanical seal, the mechanical seal of pump is very easy and simple to replace.

2. With elastic ripess assembling, the rotor parts is easy and rapid to assembly and disassembly.

3. It is unnecessary to make adjustment to any gap when assembling.

Technical advantage

With short gaps in the both ends of support, this type pump works stably with less noise and vibration. It can be risen speed operation to meet wider usage.

Being inlet and outlet located in the same center line, the pipelines arrangement looks simple and beautiful.

The rotor can be operated in reverse direction to avoid damage to the pumps from water hammer.

Unique design of high temperature, using middle support, thickening pump casing, seal cooling and oil lubrication bearing make this type pump suitable for working at 200C, especially for heat supply newtwork requirements.

This type pump case body can be vertically or horizontally installation acoording to different working condition, with mechanical seals or packing seals.

Wtih industrial designs to the shape of this type pump, the line of pump is clear and beautiful to in line with modern aesthetics.

Cost advantage

1. Using the advanced hydraulic model, the efficiency of this pump is 2%~3% higher than the same type pumps. The operating cost minimum.

2. The vacuum height of this type pump is risen 1-3 meter to reduce land construction investment and to extend the service life.

3. Using inport brand bearing, such as SKF, NSK and using various pump material make this type pump suitable for any site working condition and minimize the maintenance cost.

Maintenance advantage

1. With container type mechanical seal, the mechanical seal of pump is very easy and simple to replace.

2. With elastic ripess assembling, the rotor parts is easy and rapid to assembly and disassembly.

3. It is unnecessary to make adjustment to any gap when assembling.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia,Africa,Europe,Middle East,Americas

- Founded Year: 1982

- Address: South shaoshan, Yuhua district, changsha city

- Contact: jenny lin