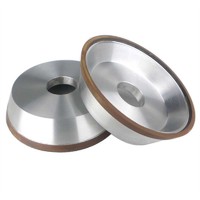

steel grinding tools CBN Grinding Wheel

Product Quick Detail

- FOB Price

- USD $50.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- 1pc per mailbox

- Delivery

- 15 Days

Specifications

Cubic Boron Nitride(CBN) grinding wheels are a revelation for the sharpening of HSS turning tools. CBN abrasive is a similar product to synthetic industrial diamonds, but a CBN wheel is far better suited for sharpening high speed steels and will withstand the friction from grinding with much less heat produced than with a diamond wheel. They produce hardly any sparks, cut quickly and efficiently and will last for many years. Plus, because it will withstand the friction the wheel doesn't wear and therefore the jig will not need to be reset. No dressing is required and they leave a nice fine and even sharp edge.

What is a CBN Grinding Wheel?

A CBN wheel

Why Use This Type of Wheel?

CBN wheels are important for grinding HSS. This is because it's a better material for sharpening and for durability, one of the best available. Diamond is harder than CBN, but over time many people have discovered that diamond is not a suitable abrasive grain and isn’t a good choice when grinding on high speed dry wheels. Choosing to buy grinding wheels with cubic boron nitrate will offer you the durability you need, while giving you the finished product you desire.

Grain Size Selection OfCBN Grinding Wheel:

| Grain Size | Machining Type | Application |

| (80#, D181), (100#, D151),(200#,D76),(230#,D64) | Rough | Regrinding A Blade Edge Profiling And Sharpening Of Much Worn Inserts |

| (1000#,D15),(1200#,D15B) | Universal | Standard Grain Size-Can Also Getting A High Sharpening Efficiency, Good Quality Machined Surfaces . |

| (1500#, D15A),(2000#,D10) | Finish | Finishing Grinding – Getting A Very Good Quality Of Machined Surfaces. |

| (4000#, D3), (5000#,D2) | Super Finish | Super Finish Grinding – Getting A Brilliant Quality Of Machined Surfaces. |

Benefits of CBN Grinding Wheels

These types of wheels have an almost indefinite life span when they are properly cared for. Many have chosen to use these wheels instead of the normal granular wheel because of their durability. The strong nature of the wheels comes from the bonding that takes place between the grains and the supporting steel hub. Thanks to this bonding feature, the wheels can be used dry without any coolant. Only a small amount of pressure is needed to sharpen a tool. The grind is very fine and there are almost no sparks when used for sharpening, unlike similar grinding wheels. The wheel remains cooler than a conventional wheel as well, making it nearly impossible to burn the tools.

One of the advantages of CBN wheels is that you can sharpen without the requirement of coolant as the wheels don't overheat or burn the tools. These wheels provide excellent removal of steel whilst also delivering a sharp edge and smooth finish with very little effort. CBN wheels have a long life as they never need to be redressed. These wheels can be mounted on a 3000 RPM or 1500 RPM bench grinder.

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: Americas,Asia,Europe,Middle East

- Founded Year: 1992

- Address: Building C28 Huachuang Industrial Park, Jinshan Village, Shiji Town, Panyu, Guangzhou-511450,China

- Contact: Frank Frank