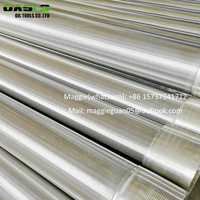

stainless steel grade/ galvanized steel wire wrapped screen

Product Quick Detail

- Place Of Origin

- China

- Minimum Order

- 1

- FOB Price

- USD $25.50 / Piece

- Type

- wire wrapped screen filters

- Packaging

- bundle bags

- Delivery

- 15 Days

Specifications

water filter well screens stainless steel strainer sand tubes

Water Well Screens

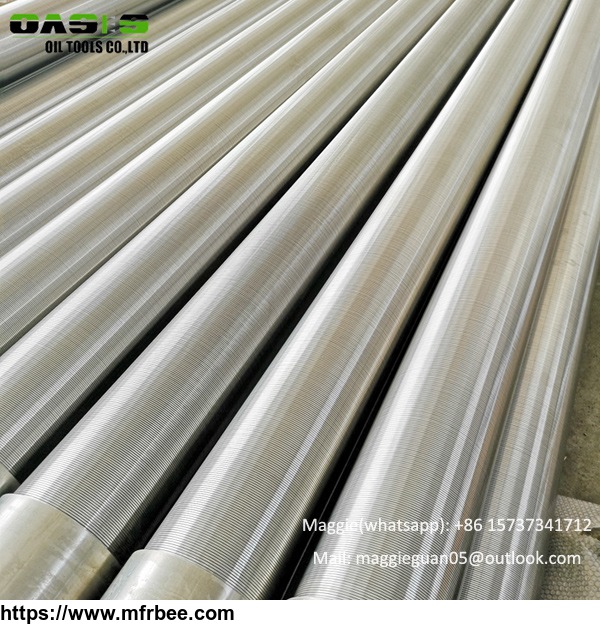

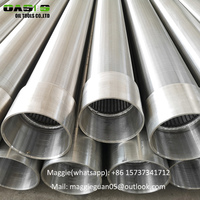

OASIS offers water well screens made from Stainless Steel SS 304. The screens are manufactured by wrapping a wire around longitudinal rods. The wire is welded to the rods by resistance welding producing a cage-shaped cylindrical configuration.

1.ADVANTAGES

Increased water flow

Reduced energy consumption

Effective and uniform well development

Improved sand control

Reduced pump maintenance

Longer well life

PROVEN PRODUCT OF PROVEN TECHNOLOGY FOR WATER EXTRACTION WORLDWIDE.

2.DESIGN OF WELDED WIRE WRAP SCREENS

The all welded wedge wire screens are made from two elements the V-shaped wedge wire is helically wound around an array of internal longitudinal support rods. Each intersection of wire and rods is automatically resistance welded, creating a very strong cage-like cylinder with one continuous slot spiralling along its full length. The gap between the wires, also called slot or aperture, is manufactured to customer specification, allows water to flow from the surrounding aquifer into the screen, The slots can be very narrow to keep out fine sand grains, which could otherwise damage your pump through abrasion.

There are several advantages a water well screen offers. They are as follows:

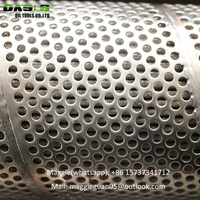

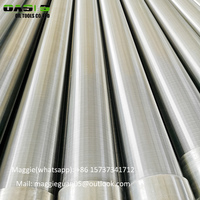

•The water well screen is a key component for controlling the sand entering the water bore circuit. The slot design of the screen resists plugging and prevents sand from damaging the pumps. The slots in the water well screens are unique in shape. The inwardly widening shape from the very edge of the slot allows only two point contact with any grain outside it. If the grain size is even marginally smaller, it slips right through without facing any resistance and is then removed out of the well with the water. The larger grains however remain outside. This design feature makes these screens non clogging type

•While the slotted UPVC pipes have least open area 10%- 15 %, the ‘V’ wire wound screen has highest possible open area (14 %-50 %). The high open area allows for water to enter the well freely resulting in minimal drawdown and less energy usage by pump

•The wire and rod construction offers required strength for specified well depth

•The unique water well screen design allows for lower entrance velocity of the water, reducing the encrustation rate

•As the screen is made from stainless steel it offers maximum corrosion resistance for water chemistry

•The right selection of slot size is made after below ground sand sample analysis. The slot size, diameter, and the length of the screen can be customized to suit the requirement of the well

Our company:

Oasis oil tools co.,ltd has been awarded many honors and certifications such as patents of utility model authorized certificate, quality management system certificate, export licence and pre-export licenses. We can design all types of letters of credit according to your requirement. Oasis oil tools co.,ltd has developed into a famous and leading manufacturer which integrate the research and development, design, manufacture and sell. Welcome to visit our company.

Welcome to contact with us for more details:

http://www.oasiswellscreens.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Emerging Markets,Europe,Middle East,Oceania

- Founded Year: 2012

- Address: Fengquan industrial Park

- Contact: Maggie Guan