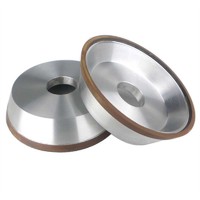

Diamond and CBN Face Grinding Wheels

Product Quick Detail

- Place Of Origin

- China

- Minimum Order

- 1

- FOB Price

- USD $50.00 / Piece

- Packaging

- 1pc per mailbox

- Delivery

- 15 Days

Specifications

Diamond and CBN Face Grinding Wheels for Roughing and Finishing

Face grinding in through-feed processes with diamond and CBN grains has firmly established itself in the market. Grinding wheels with porous bonding systems have gained acceptance due to their

technological advantages such as high stock removal, continual heat dissipation and reduced wear. New bonding systems now make it possible to achieve significant improvements in service life as

well as greatly reduced machining times.

Benefits of Face Grinding:

• Reduced cutting forces

• Increased removal rates

• Highest part quality

• Ideally profiled dressed wheels work in the self-dressing range of the machine

• Increased precision

• Easy repairs simply by replacing individual abrasive segments

• Reduced machine downtime

1A2 diamond and CBN grinding wheels used for precise edge grinding of indexable inserts, tungsten carbide inserts, ceramic inserts, CBN inserts.

Materials of workpiece: tungsten carbide, ceramics, PCD/ PCBN inserts, etc

12A2 diamond and CBN grinding wheels used for sharpening and finishing of front surface of reamer teeth,hobbing cutters,circular saws,drawing dies and tools made of hard alloys.

*The abrasive layer of 12A2 grinding wheel is made of synthetic diamond powder in resin or vitrified bonds.

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: Americas,Asia,Europe,Middle East

- Founded Year: 1992

- Address: Building C28 Huachuang Industrial Park, Jinshan Village, Shiji Town, Panyu, Guangzhou-511450,China

- Contact: Frank Frank