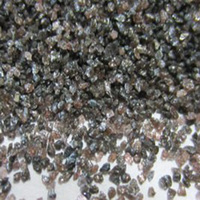

cheap brown aluminum oxide manufacturer in china

Specifications

In a word, the phase, microhardness and microdefects of bond in abrasives should be analyzed in combination with the use of abrasives and the main requirements of abrasives, and other physical and

chemical properties of bond, so as to get a comprehensive concept, which can be used as the basis for choosing bond. Both white corundum and brown corundum contain alumina, and the hardness ofwhite

corundum

First of all, the white corundum sand can replace the staggered quartz sand because the anti sticking effect of the staggered quartz powder coating is better, and the high-temperature performance

of the staggered quartz powder is very good. Compared with the high-temperature performance of the white corundum powder, the high-temperature performance of the white corundum powder is not as

good as that of the white corundum powder, making the white corundum powder coating easy to produce problems such as the sand sticking weight of the casting surface.

In winter, the road surface is prone to waterlogging and slipping in rainy and snowy days, which corrodes the bridge steel plate, and the anti-skid performance is poor in freezing weather. The new

bridge no longer uses the rubber plate to pave the bridge deck, but boldly uses the new material black corundum in the bridge deck reconstruction. Practice has proved that the application ofwhite

fused alumina

When the white corundum is smooth and spherical, or the columnar white corundum polycrystal is arranged in vertical pure cotton, and the rock is brittle, the drill bit is mainly broken rock under

the combined action of rotating torque of axial pressure box. When the white corundum is multi angular, or triangular white corundum polycrystal is arranged in the tangential direction of angular

rotation and angular rotation, or the white corundum composite sheet is used, and the rock plasticity is relatively good If it is large, the hole following mechanism of the bit is similar to that

of the milling cutter or the micro cutter.

Adding brown corundum to the refractory can make its performance more stable and improve its performance at the same time. Sandblasting is mainly used in copper, aluminum, glass, ceramics, jeans

and other related fields, whilewhite aluminum oxide

When it is used for the surface coating, it can easily get a bright and clean casting surface. The content is more than 99%, and the alumina content of brown corundum is more than 95%.

Due to the high alumina content of white corundum, the color is white, and the brown corundum is brown black. Brown corundum is characterized by high purity, good crystallization, strong

fluidity, low coefficient of linear expansion and corrosion resistance. Through the practice of dozens of fire-resistant production enterprises, the product has the characteristics of non

initiation, non pulverization and non cracking in the application process.

- Country: China (Mainland)

- Business Type: 制造商

- Market: 欧洲,美洲

- Founded Year: 2000

- Address: No.3220,HengTai International Building

- Contact: Terry Ma