Gypsum Board Laminated Equipment

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China

- FOB Price

- USD $50,000.00 / Piece

- Packaging

- N/A

- Delivery

- 60 Days

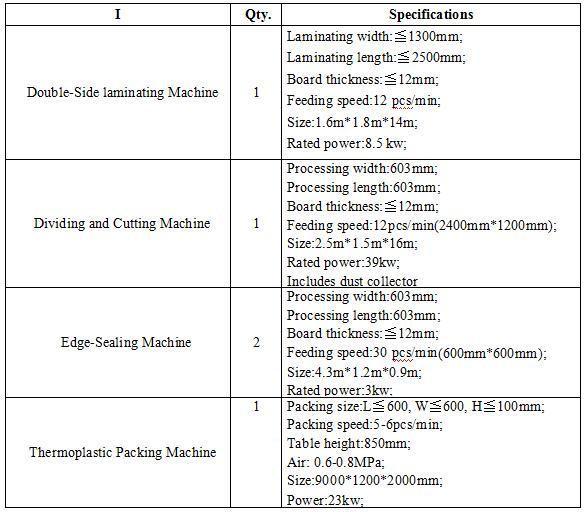

Specifications

1. Type of Production Line

Production capacity: 6 million sqm/year (Calculate by 24hrs/day and 300 working days per year)

Power: 380V/50Hz; 3 phase

Size of boards (L*W):1220mm*1830mm;

Size of Finished product (L*W): 600mm*600mm

Thickness:6-12 mm

Films on front side of board: PVC films

Films on back side of board: Aluminum films

2. Equipment List

3. Description of Machines

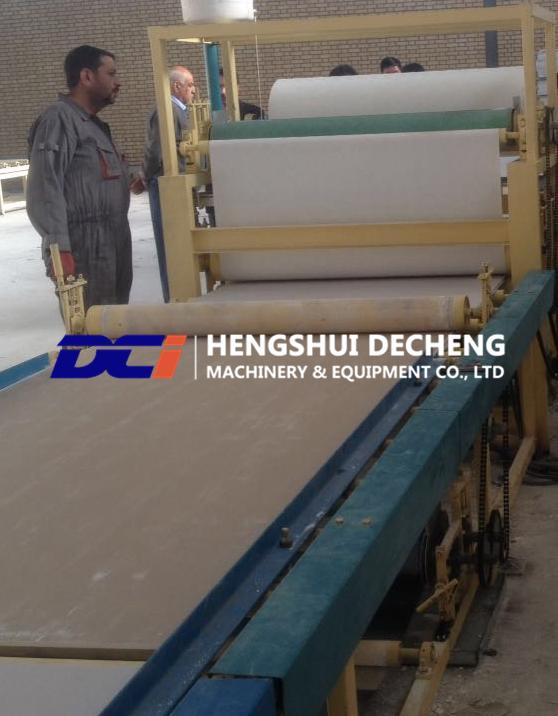

3.1Double-Side laminating Machine

It includes gluing device,rolling device and flattening device. It can work with two side (front side PVC film, back side aluminum film) at same time, no need to turn it over. It is widely used for coating the surface of density board, multilayer plywood, joinery board, glass, acrylic, mosaic,all kinds of flat plate.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Emerging Markets,Europe,European Union,G20,Middle East,Oceania

- Founded Year: 2008

- Contact: Jing An