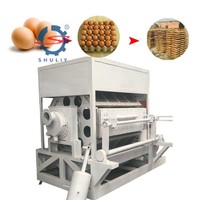

New egg tray production line

Specifications

The production cycle of the egg tray machine production line is a cycle that consists of a downward movement of the mold, suction, upward movement of the mold, cold extrusion molding, hot pressing, and material transfer. The entire process of the egg tray machine is a sequential process, so the use becomes The controller realizes sequential action cycle control. The main technical difficulty lies in that: the pulp molding production process includes two processes: cold extrusion and hot pressing.

website:https://www.eggtraymaking.com/egg-tray-making-machine/

Egg tray machine

1. Pulping system: including pulper, refiner, mixer, pulp pump, water pump, control cabinet, etc. The pulping system is the first step of an egg tray production line. This step mainly puts waste paper into a pulper. After a series of processes such as pulverization and stirring, the fixed-concentration pulp required for egg tray forming is reconciled into Preparing for molding. The pulper has 1.2 cubics, 1.5 cubics, 3 cubics, 5 cubic and so on. The actual capacity can be customized according to the customer\'s specific requirements for output.

2. Forming system: The forming machine of the HR-1000 small egg tray production line has a total of 3 forming molds and 3 transfer molds. The forming efficiency is 6-8 plates/minute, and it is equipped with an automatic control cabinet. This process mainly uses vacuum adsorption molding technology to make the egg pulp, egg carton, fruit tray, bottle tray, industrial packaging product tray, etc. from the pulp prepared in the first step.

3. Drying system: There are two types: natural drying and metal drying. The conveyor chain plate of the metal drying line is a single layer, with direct-fired hot air circulation, using imported brand burners, and equipped with automatic control cabinets.

- Country: China (Mainland)

- Founded Year: 2011

- Contact: allen guo