Pummel Test Device

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- 1 Set each Plywood Case

- Delivery

- 7-15 Days

Specifications

Pummel Test Device

Application: Pummel test equipment for detect the adhesion of the interlayer of the laminated glass.

Data:

Hammer head diameter: 30mm

Impact Distance: Adjustable

Voltage: 380v

Whole machine voltage: 0.80KW

Test machine size: 1250 mm *1130 mm *870 mm long *wide *high

Control cabinet size: 560mm * 450mm * 1090mm long * wide * high

Knocking frequency: 220 times/min

Maximum sample size: 300 mm x 300 mm

Maximum knock size: 300 mm x 200 mm

Sample applicable thickness: 4mm-6.5mm

Pummel Test device

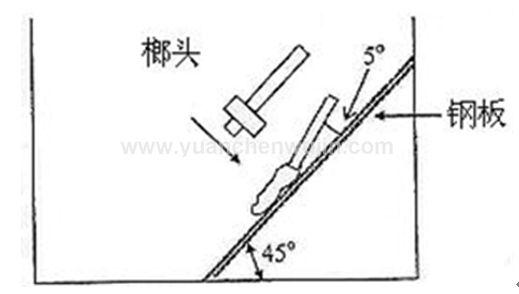

The test device used a knock test chamber as shown in Figure below and a 454 g flat iron hammer

Sample preparation

According to the normal glazing process, 3 pieces of laminated glass samples of 2mm colorless transparent glass + 0.76mm PVB + 2mm colorless transparent glass were prepared, and the sample size was 300 mm × 76 mm.

Test procedure

The sample was placed in an environment of -18 ° C ± 1 ° C for 2 hours, and immediately taken out and placed in a percussion test chamber for testing. The glass was struck with a hammer from the bottom of the sample until the glass was cut about 200 mm along the length of the sample, as shown in Figure below。

After the correct tapping, the original surface of the glass should be broken and broken into small particles. After the crushed sample was placed for 30 min, and the surface of the glass was free of condensed water, the area of the bare film was statistically calculated, and the tapping value of the sample was determined according to Table below.

Determination of the value

| Surface area of PVB film exposed after pummelS(%) | Pummel Value |

| 95≤S≤100 | 0 |

| 90≤S<95 | 1 |

| 85≤S<90 | 2 |

| 60≤S<85 | 3 |

| 40≤S<60 | 4 |

| 20≤S<40 | 5 |

| 10≤S<20 | 6 |

| 5≤S<10 | 7 |

| 2≤S<5 | 8 |

| S<2 | 9 |

- Country: China (Mainland)

- Market: China inland and other countries all over the world

- Founded Year: 2006

- Address: Northern Industrial Area, Haigang District, Qinhuangdao, Hebei, P.R.China

- Contact: Magoo Liu