Ball Mill

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

The Handling Materials and Main Types of Ball Mill:

Ball mill is a key equipment for grinding materials, widely used in powder-making production line such as cement, silicate sand, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc.

Ball mill can grind various ores and materials with the dry type or wet type. There are two kinds of ball mills, grate type and overfall type due to different ways of discharging material.

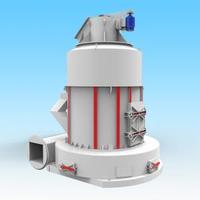

The Interior Structure of Ball Mill:

The machine is composed by feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control). The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which has good wear-resistance. The machine is in stable and reliable working condition.

Moreover, according to different materials and discharging methods, there are dry ball mills and wet ball mills for choice.

The Working Principle of Ball Mill:

This machine is a skeleton pattern ball mill with horizontal cylindrical turning gear, drive by outer gear and two hoppers. The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment. The hopper has ladder sheathing or corrugated sheathing with steel balls inside, which will fall under the effect of centrifugal force by the barrel and grind material. After the kibbling in the first hopper, by monolayer partition panel, the material will enter the second hopper, which has plane scale board with steel ball inside to grind material. The powder material will be discharged from the grid plate to finish the grinding.

Ball mills are widely used in production industries, such as cement, silicate products, new building materials, refractory materials, chemical fertilizers, black and ferrous metals and glass ceramics and others. It can grand things in dry-type and wet-type for all kinds of ore and other grindable materials.

The Structure Characteristics of the Ball Mill

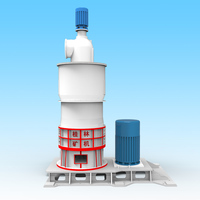

Theindustrial ball mill

Quick-wear Parts of the Ball Mill

The quick-wearball mill parts mainly refer to the lining boards, the wear and usage time of the liner are related to the cost and production effect of theball mill crusher

The Operation Principle of the Ball Mill

The material is entered into the hollow shaft by the feeding device, and then it enters the first warehouse of the ball mill evenly. There are stepped lining plates or corrugated lining plates with different sizes of steel balls inside the warehouse. The cylinder rotates to produce centrifugal force for bringing the steel ball to a certain height and then it falls down. This produces heavy blow and grinding effects to the material. After the rough grinding process, the material enters the second warehouse through a single clapboard. The warehouse is lined with a scale-board with steel balls for further grinding. The powder is discharged by the discharging grate plate to finish the grinding operation.

The Classifications of the Ball Mill

According to the different materials processed by the ball mill,Guilin Mining Machinery

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:1973

- Address:No.1 Guikuang Road, Lingchuan County, Guilin City, Guangxi Province,China

- Contact:Ralap Zeng

Other products from Guilin Mining Machinery Co., LTD.

Relate products of Ball Mill

TheCommercial Wood Pellet Millis an essential piece of equipment for converting raw wood materials into high-quality wood pellets. These pellets are widely used as a sustainable and renewable source of energy. TheCommercial Wood Pellet Milloperates efficiently, ensuring a ...

PCD/PCBN铣刀特点: ▲刃口采用激光技术,刃口锋利,切割轻盈,适合高速场合。 ▲中等粒度的PCD兼具耐磨性和抗崩刃性,综合性能优良。 ▲同一规格的直径,切削刃长度不同。 ...

Product Item: Electric Ball Valve. Material: ASTM A216 WCB. Size: 4 Inch, DN100. Pressure: Class 150 LB, PN20. Design Standard: API 6D. For ...