Automotive Mold

Product Quick Detail

- FOB Price

- USD $5,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- PALLET

- Delivery

- 4 weeks

Specifications

PlasticAuto Parts Mould

HanKing Mould

Vehicle Switch Mold Tooling

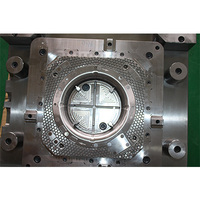

Mould Name: Switch Mould for carPart Material: Dupont Zytel Product Size: Product Description: Switch PieceMould Cavity: 8 Cavities Automotive SwitchMould Size: Suitable Injection Machine:Mould Cavity Steel...

High Precision Auto Injection Mould for Fuse

HanKing Mould produce all different kind fuse and connector protector for international OEM company, we have a lot of experience to short the project development time.

Precision Automotive Parts

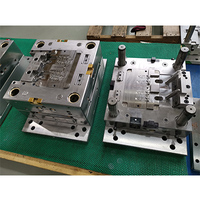

Mould Name: Precision Automotive Mould Part Material: PA66 G30Product Size: Product Description: BODY plastic Mould Cavity: 4 Cavities MoldMould Size: Suitable Injection Machine:Mould Cavity Steel...

Electrode of Auto Plastic Component Mould

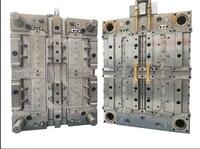

HanKing Mould produce all different kind fuse, connectors and electordes for international OEM company, we have a lot of experience to short the project development time.Mould Name: Electrode of Auto...

Car Parts Mold

Plastic Injection Mould in HanKing Advantages:1. Professional mould designers; 2. Rich mold making experience, well know standard from different country; 3. Stable and high quality but reasonable price; 4. On time delivery, fast mold development schedule.

OEM Plastic Housing Auto Parts Mould

Specialize in providing plastic injection moulds & molding service to global clients.We provide OEM Plastic Housing Auto Parts Mould to the customers from Germany, USA, Mexico, Italy, Israel...

- Country: China (Mainland)

- Founded Year: 2011

- Address: No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen. China.

- Contact: Yoyo Tang