Insert Molding Technologies for Automotive Industry

Product Quick Detail

- FOB Price

- USD $5,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- PALLET

- Delivery

- 15 Days

Specifications

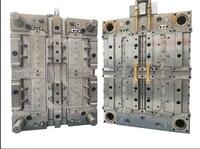

Insert Molding Technologies

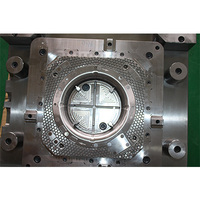

Mould Type: Automotive Sensor Plastic Injection Mould

Production Material: Nylon PA66

No of Cavities: 4 cavities

Core Material: S7

Cavity Material: S7

Mold base steel: 1.1730 with A/B plate 1.2312

Injection System: Cold runner

Type of gating: sub gate

Ejection system: Round ejector pins

Lead time: 6 weeks

Shot life: 1,000,000

Export to: America

Feature: 2 times over molding

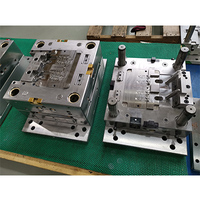

Excellent mould design and tool construction are very important in insert molding to keep tooling reliability and part tolerances.

In HanKing Mould, a project manager control your plastic parts project from concept tooling design to delivery, our project manager has both design and project management experience, the project manager will connect customer and every work phase from design confirmation, mould building, insert molding trial, low volume production, etc.

HanKing mold making tolerances

Plates and Mold Base Components: ± 0.013 mm (± 0.0005 in)

Cavity components: ± 0.005 mm (± 0.0002 in)

Related Products

Media Center

Heat Treatment Characteristics Of Custom Molds For Plastic

1. For custom molds for plastic with high hardness, high wear resistance and high toughness, carburi...

How to Processing Precision Dies

The precision mold & machining process is the last process of die processing, and it is the most imp...

What is Precision Injection Molding

What is Precision Injection Molding

Precisioninjection moulding

- Country: China (Mainland)

- Founded Year: 2011

- Address: No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen. China.

- Contact: Yoyo Tang