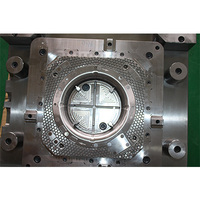

Prototype Mould

Product Quick Detail

- FOB Price

- USD $5,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- PALLET

- Delivery

- 4 weeks

Specifications

Soft Prototype Mold

Prototype Mould is a kind of test mould before mass production mould, customer make test mould for design verification, Product structure, part function analysis or produce small lot parts for other...

As a tool supplier whose goal is becoming an expert in the industry,HanKing Mould

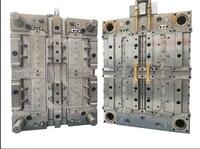

Prototype Mould is a kind of test mould before mass production mould, customer makes test mould for design verification, product structure, part function analysis or produces small lot parts for other process verification. Prototype moulds are usually different from production moulds as they are not usually intended to be used for long periods of time.

Prototype molds are also called soft moulds or fast moulds, thus the cost of prototype molds are less than serious plastic moulds, when our designer is constructing a prototype mould, the first point he should learn is the purpose of customer to make this prototype mold.

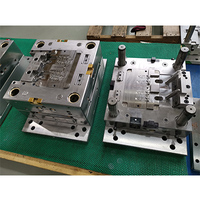

Some customers' goal is to manufacture low-cost pre-production molds that are tested and troubleshooting prior to final serious production to obtain more engineering data

Some customers have reduced the overall product development cost of manufacturing low-cost prototype molds simply because of the low production of parts in demand.

Some clients are purposed to get fast samples or small batch quantities, for another process testing, such as electrical engineering testing, painting test, etc..

If you are not sure if the final parts are functional ok and how to build a production mould, as a professionalprototype mold making

Related News

Parting Line Design in Mold Making

Global Precision Mould Material Conference

Personalized Customization Becomes the Trend of Manufacturing Industry

Injection Mold Building Process

How to Processing Precision Dies

Advantages of Chinese Mould Enterprises

- Country: China (Mainland)

- Founded Year: 2011

- Address: No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen. China.

- Contact: Yoyo Tang