PDC (Polycrystalline Diamond Compact) Cutter

Product Quick Detail

- Place Of Origin

- china

- Minimum Order

- 6

- Packaging

- Box

- Delivery

- 2-7 days

Specifications

We havePDC Cutters for sale!

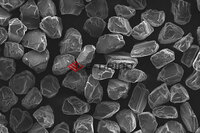

PDC cutter containspolycrystalline diamond cutters

Application: Oil & Gas and Mining.

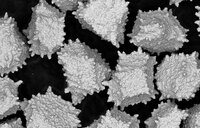

Diamond Enhanced Cutter (Dome PDC Cutter)

Diamond enhanced cutter (DEC) is synthesized by diamond particle and tungsten carbide supporting layer at high pressure and high temperature. It is the best replacement to tungsten carbide insert.

It combines both the high wear resistance of diamond and high toughness of carbide.

Application: high-class PDC bits as the gauge, anti-vibration, or center cutters, percussion bits, cone bits, mining picks, PDC bits ...

E-Grind supplies Diamond Enhanced Cutter (Dome PDC cutter) with various shapes: spherical, conical, bullet-shaped, wedge… Our DEC has high impact resistance and wear resistance.

E-Grind provides full ranges of PDC specs. Three series are available:

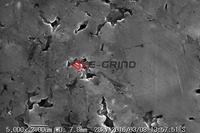

EA-PD1

The Diamond section is with flat tine junction plane. The thickness of the diamond layer is about 0.8~1.2mm. It is mainly used in stone processing and hole (blind hole) can be punched according to customers' requirements.

E-Grind Abrasives is professional insuperabrasive

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Americas,European Union

- Founded Year:450000

- Address:Room 1841, Tower A, Wanda Plaza, 171#, Zhongyuan Road, Zhengzhou City, Henan Province, China

- Contact:locke liu

Other products from Henan E-Grind Abrasives Co., Ltd.

Relate products of PDC (Polycrystalline Diamond Compact) Cutter

Description:PDC cutter is mainly applicable for PDC drilling bit for drilling into soft and intermediate-hardness stratum. Details The specifications of PDC cutter for oil drilling bits(PDC Rock Cutter for Oil Well Drilling Bits) PDC - F (flat cutter ):The flat surface combines ...

Overview of PDC Hole Opener Drill bit opener is designed for the enlargement of pilot holes and large hole applications. They are also used for road and river crossing applications. The hole opener is made of AISI 4145H fully heat-treated alloy steel. All products have carbide ...

Overview of PDC Cutter PDC cutters are made of diamond micro-powder and cemented carbide substrate sintered under ultra-high pressure and high temperature. It has high hardness, high wear resistance and thermal conductivity of diamond, and has the strength and impact toughness ...