Factory price AFS30 ceramic foundry sand

Product Quick Detail

- Place Of Origin

- china

- Minimum Order

- 1

- FOB Price

- USD $568.00 / Piece

- Packaging

- 25kg/bag

- Delivery

- 15 Days

Specifications

Factory price AFS30 ceramic foundry sand

Ceramic Sand Replacing Foundry Chromite Sand

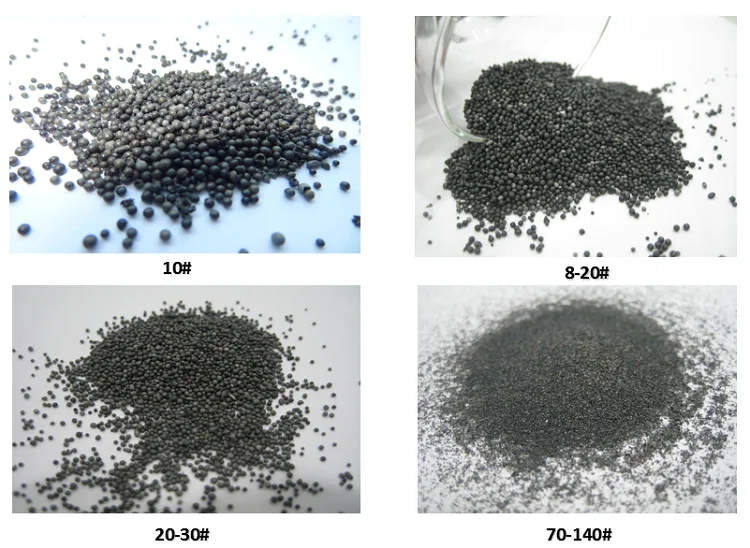

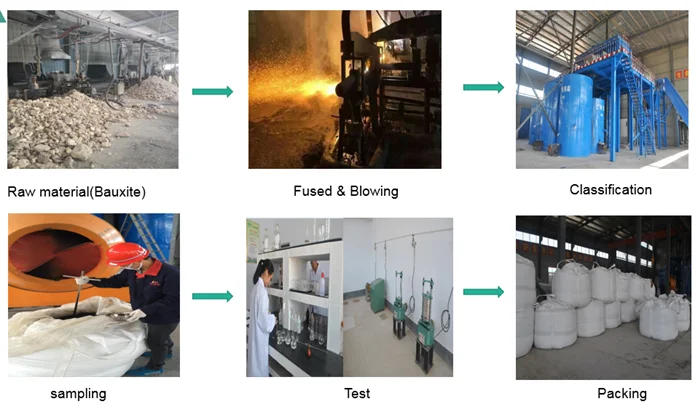

Ceramic foundry sand is made of high quality bauxite, through the process of electrofusion, granulation, screening and so on,which is made of very ball-like refractory particles.

Ceramic foundry Sand for Casting Chemical and Physical index

| Shape | Round |

| Color | Dark brown |

| Bulk density | 1.95-2.05g/cm3 |

| Real density | 3.4g/cm3 |

| Refractory temperature | ≥1800℃ |

| Thermal expansion | 0.13% |

| Thermal conductivity | 0.698W/M.K |

| Angularity | ≤1.1 |

Chemical composition

| Composition | Content(%) |

| Al2O3 | >70 |

| SiO2 | 15-25 |

| Fe2O3 | <3 |

| TiO2 | <3.5 |

| CaO | <0.45 |

| MgO | <0.35 |

| K2O | <0.33 |

| Na2O | <0.08 |

Ceramic foundry Sand for Casting product Line

Applications

| 1 | Widely used in foundry technique like resin-bonded sand, sodium silicate sand, and clay- bonded sand for sand core and casting mould making |

| 2 | Replace chromite sand and widely used in sand core making like jacket core, oil duct core, tappet core of engine. |

| 3 | Replace chromite sand for steel casting facing sand and sub-layer of molding sand (backing sand). |

| 4 | Widely used as dry sand and sand box for EPC process and V method of casting processes. |

| 5 | Widely used as the main raw materials of advanced refractory products (Ladle drainage sand,gravity casting material, casting coating, etc.). |

| 6 | Widely used as cleaning sand for copper and aluminum alloy castings |

Contact us

Ceramic foundry sand AFS30# price Contact Us:

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: Europe,Asia,Oceania,European Union,Emerging Markets

- Founded Year: 2010

- Contact: Ms.Chen