SONDEX Plates And Gaskets

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- 50 pcs in Carton box

- Delivery

- 15 Days

Specifications

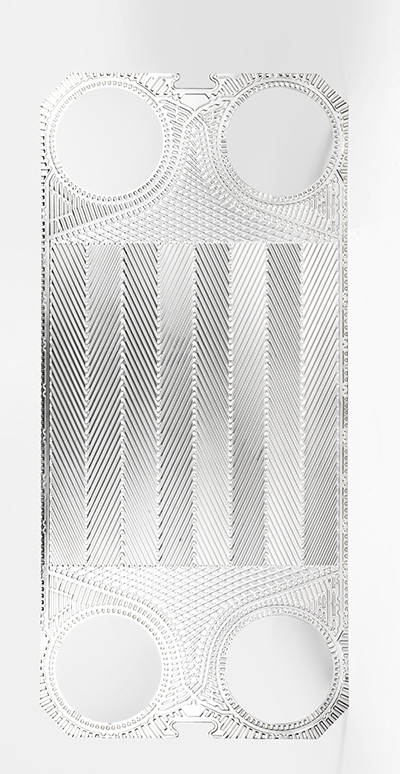

Product Feature

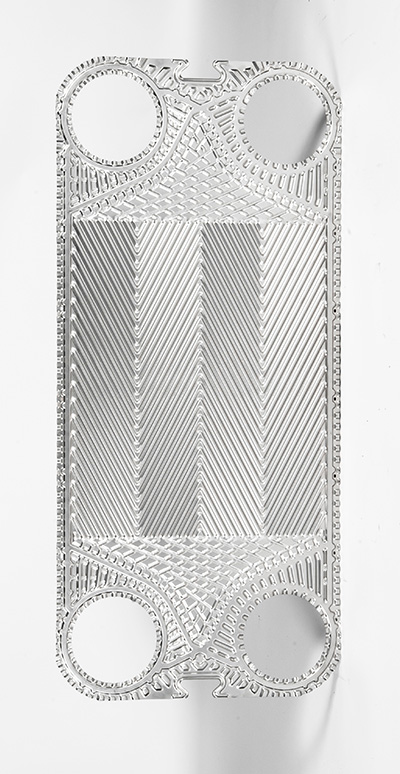

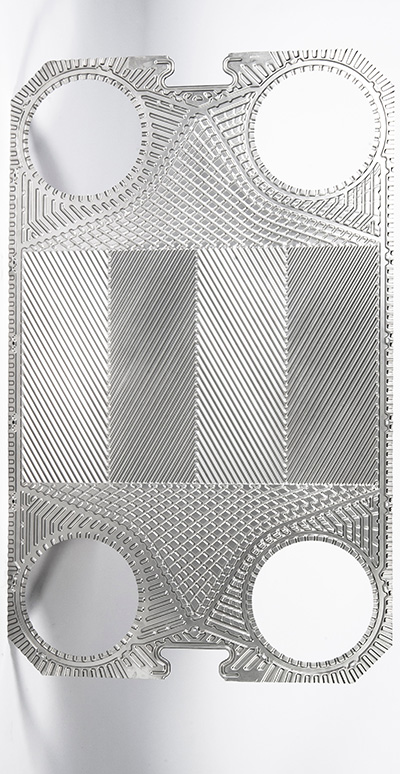

1. Using ultra-fine mesh numerical simulation technology to make the plate flow and heat transfer performance superior.

2. Select different plate spacing ratio to get the best matching plate type, making heat exchangers run perfectly.

3. Unique corrugated and flow channel design enables the medium to generate strong turbulence.

4. Contact points formed between the chevron corrugated plates, so the pressure-bearing is high.

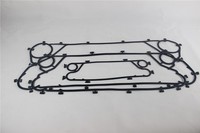

5. Sealing gasket "convex" section design, with large sealing force, not easy to leak, easy to install.

6. Outer protrusion of the gaskets matched with groove on back of plates to avoid misalignment,

7. Two seals type of gaskets prevent two medium mixing.

Product Display

-

S7A

S7A -

S14

S14 -

S42

S42 -

S43

S43 -

S121

S121

Product Model

| SONDEX model | |||||

| S4A | S19A | S37 | S47 | S86 | SFD13 |

| S8A | S20A | S41 | S62 | S100 | SFD22 |

| S7A | S21 | S41A | S63 | S110 | SFD23 |

| S9A | S21A | S42 | S64 | S113G | SFD35 |

| S14A | S22 | S43A | S65 | S121 | SF123 |

| S16B | S31A | S43 | S81 | S188 | SF160 |

| S17 | | | | |

- Country: China (Mainland)

- Market: worldwide

- Founded Year: 2014

- Contact: Joey wong