Head-Form Test Device ISO 3537

Product Quick Detail

- FOB Price

- USD $420.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- Plywood Case (Meet import and export requirements)

- Delivery

- 15 Days

Specifications

Related Standard:

ISO 3537 Road vehicles –Safety glazing materials — Mechanical tests – Clause 10 Head-form test

Principle: Assessment of the minimum strength and cohesion of the safety glazing material under impact from a blunt, bulky object. If required, tests can be performed on whole windscreens.

Application:

The purpose of this test is to verify the compliance of glazing with the asking relating to the limitation of injury in the event of impact of the head against the windscreen, laminated glass and glazing of glass-plastic and rigid plastic other than windscreens, together with The double-glazed units used in the side windows.

Techinical Data:

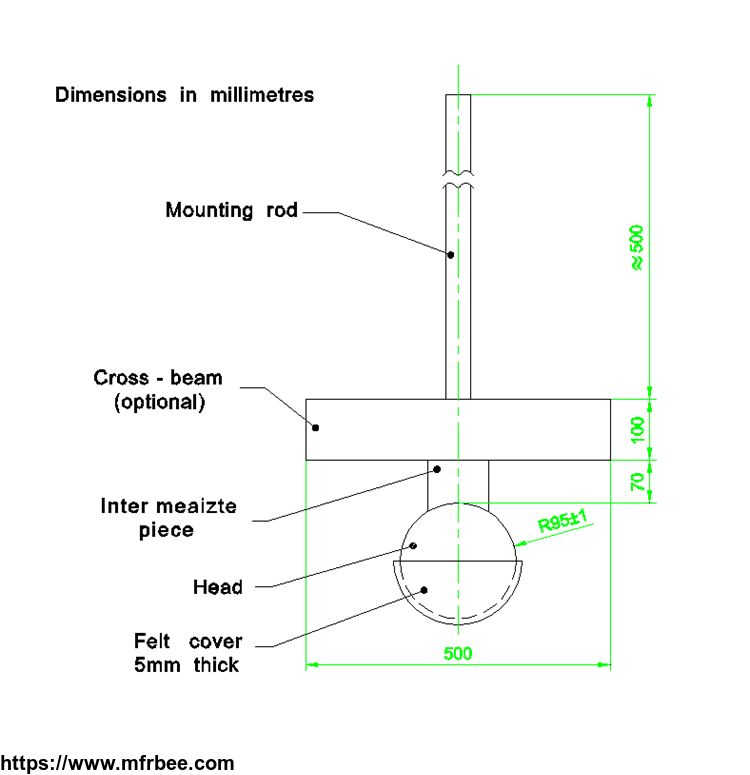

Head-form Weight: 10kg

Head-form Size: 500mm*932mm

Impact height: < 1.5m

Samples size: 1100mm*500mm

Felt hat: 90g/89mm Thickness:5mm

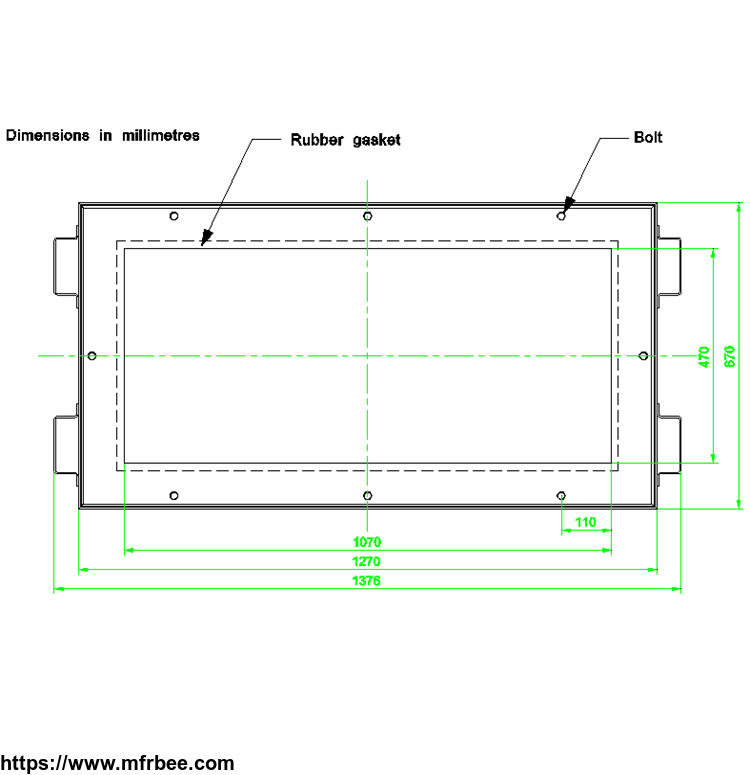

Frame size: 1376mm*670mm*320mm

Apparatus:

Head-form weight, with a spherical or semi-spherical head made of laminated hard wood covered with replaceable felt and without a cross-beam made of wood. Between the spherical part and the cross-beam, there is a neck-shaped intermediate piece and on the other side of the cross-beam, a mouning rod.

The total mass of the apparatus shall be 10kg±0.2kg

Supporting fixture:

for testing flat test piece, the fixture is composed of two steel frames, with machined edges, 50mm wide, fitting one over the other and faced with rubber gaskets 3mm±0,5mm thick and 15mm±1mm wide, of hardness 70 IRHD.

The upper frame is pressed against the lower frame by at least eight bolts. The support shall rest on a rigid stand with a sheet of rubber, of hardness 70 IRHD and 3mm±0,5mm thick, placed in between.

- Country: China (Mainland)

- Market: China inland and other countries all over the world

- Founded Year: 2006

- Address: Northern Industrial Area, Haigang District, Qinhuangdao, Hebei, P.R.China

- Contact: Magoo Liu