Boil Test Apparatus AS/NZS 2208

Product Quick Detail

- FOB Price

- USD $595.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- Plywood Case (Meet import and export requirements)

- Delivery

- 15 Days

Specifications

Application

Determining the effect of exposure of safety glazing material to temperature and humidity conditions by boiling

PRINCIPLE

Specimens are immersed in hot water and then boiling water for a

specified period of time and inspected for bubbles or other defects.

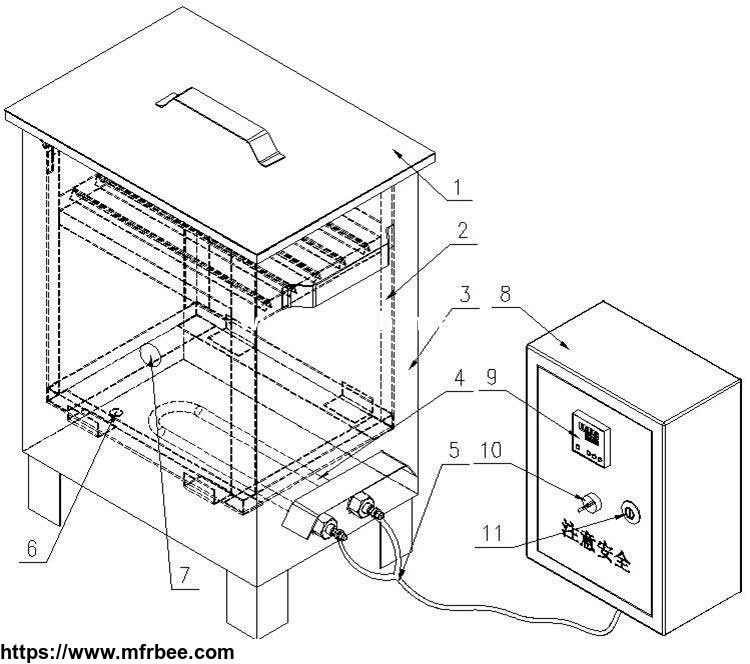

5: Power cord 6: drain hole 7: Probe 8: Power distribution cabinet

9: Temperature control table 10: power switch 11: Distribution cabinet lock

Composition

Two water baths each of sufficient size to hold the test specimen fully immersed vertically on edge, for the duration of test.

Samples

Three specimens of size 300 mm × 300 mm manufactured in a manner

identical with the impact test specimens (see Appendix B) and of like thickness shall be tested. These specimens may be cut from production samples of the size and thickness submitted for impact testing. For heat strengthened or toughened laminated glass, test specimens may be cut from a similar original sheet of annealed laminated glass.

Procedure

a) Immerse the specimens vertically on edge in a bath of water maintained at a temperature of 66 ±3°C for 3 min.

(b) Quickly transfer the specimens to a bath of water maintained at boiling point. Immerse the specimens vertically on edge in the bath for 2 h.

(c) Remove the specimens and examine for bubbles or other defects.

- Country: China (Mainland)

- Market: China inland and other countries all over the world

- Founded Year: 2006

- Address: Northern Industrial Area, Haigang District, Qinhuangdao, Hebei, P.R.China

- Contact: Magoo Liu