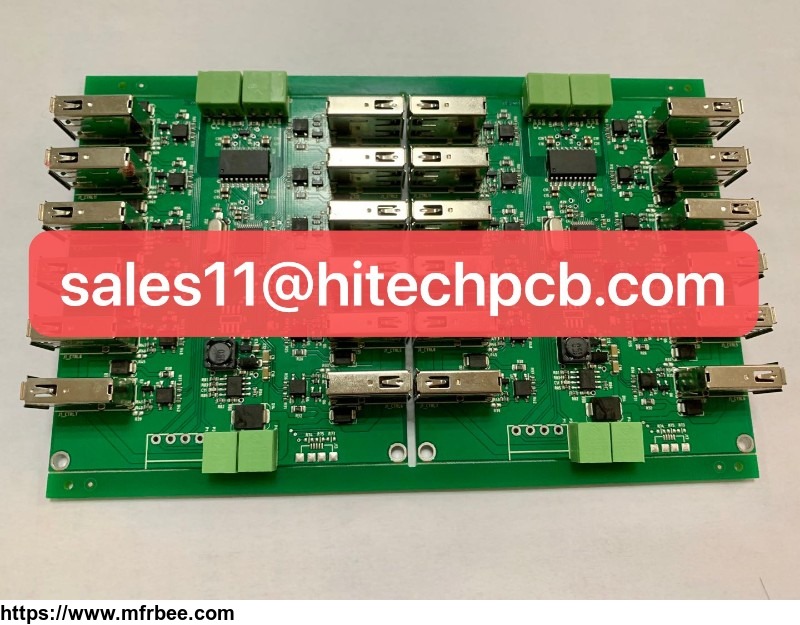

PCB Assembly and Components Sourcing

Product Quick Detail

- FOB Price

- USD $16.00 / Piece

- Minimum Order

- 5

- Place Of Origin

- China (Mainland)

- Packaging

- card board, foam, carton

- Delivery

- 15 Days

Specifications

PCBA appearance inspection instructions

1,The lack of components: In the corresponding position, no solder components in accordance with the requirements.

2,dry soldering: component not tin or the tin is less than three-quarters of the solder joint area (SMT components for the solder area is less than the width of 1/2 of component).

3,continuous tin electrodeposit: due to abnormal operation, connect of two point which are disconnected on the electrical with tin.

4,Error components: the components which is soldered on board is not match with the BOM.

5,Pseudo Soldering: Component’s pin is not solder well, can not guarantee effective welding (including fake welding).

6,Cold welding: welding surface is gray, no wetting well.

7,Reverse: The polarity of the component after mounting is opposite to that specified in the document.

8,Build monument: One end of the components tilt away from the pad to form a monument.

9,Positive and negative solder wrong:The front of the assembly (silkscreen side) faces down but the soldering is normal.

10,Open circuit: Component’s pins are disconnected or the PCBA board line is disconnected.

11,Tipped: Line copper foil or pad detached from PCBA board and raised beyond specification.

12,Excess components: The file indicates the location of a component without the presence of components on the PCBA board.

13,Tin cracking: usually after the solder joint is subjected to external force, the solder joint and the component lead are separated, which has an impact on the welding effect.

- Country: China (Mainland)

- Contact: Cynthia u