HPMC for Gypsum Plaster

Product Quick Detail

- FOB Price

- USD $2,300.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- bags

- Delivery

- 7 Days

Specifications

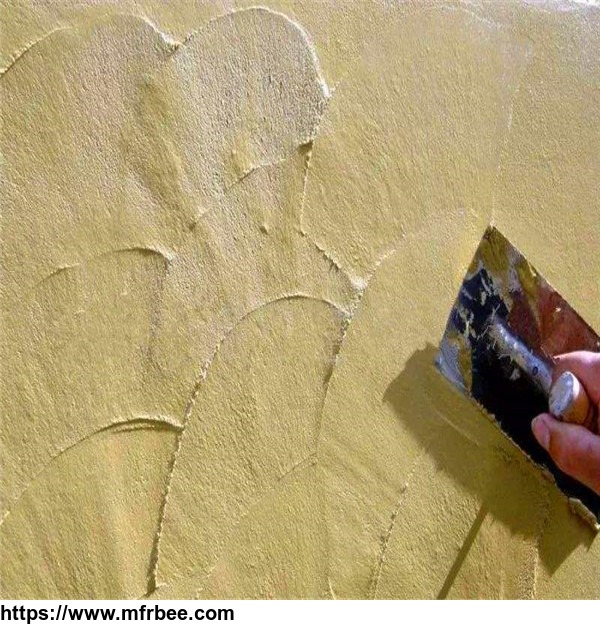

HPMC for Gypsum Plaster

HPMC Description:

Hydroxypropyl Methyl Cellulose (HPMC)

HPMC is non-ionic cellulose ether made from natural cotton fiber under series of chemical

processing.

It’s odorless, tasteless and non-toxic white powder, can be dissolved in normal water to form a

transparent viscous solution with the properties of thickening, binding, dispersing, emulsifying, film coating, suspending, absorbing, gelling, water retention and colloid protection.

Physical Properties:

| Appearance | White to off-white powder |

| Hydroxypropoxy% | 4-12 |

| Methoxy % | 25-30 |

| Viscosity (NDJ-1) | 65000Mpas-200000Mpas |

| Gel Temperature | 65-75 °C |

| PH | 5.0-8.5 |

| Water retention | 93-98 |

| Moisture | Max 5% |

| Ash Content | Max 5% |

Rotational Viscometer/NDJ-1 2% Solution 20℃

HPMC Typical Application:

1.Tile adhesive /Tile grout.

2. Wall putty/Skim Coat.

3.Gypsum Plaster.

4. ETIFS mortar.

5. Self-leveling cement mortar.

6. Flexible crack resistant mortar.

7. ETRIS(external thermal insulating rendering systems made of mortar with mineral binder and

using expanded polystyrene granule as aggregate) mortar.

8. Blocks/Panel Jointing mortars.

9. Polymer mortar products which has high requirement on flexibility.

HPMC Function:

Thickening Agents

Water Retention Agents

Enhance Cement bond

Improve adhesive strength

Weathering Resistance strong

Easily and Smoothly Construction

No Chalking, No Cracking, No tile Falling off, Safety working.

- Country: China (Mainland)

- Founded Year: 2002

- Contact: Laura Zhao Zhao