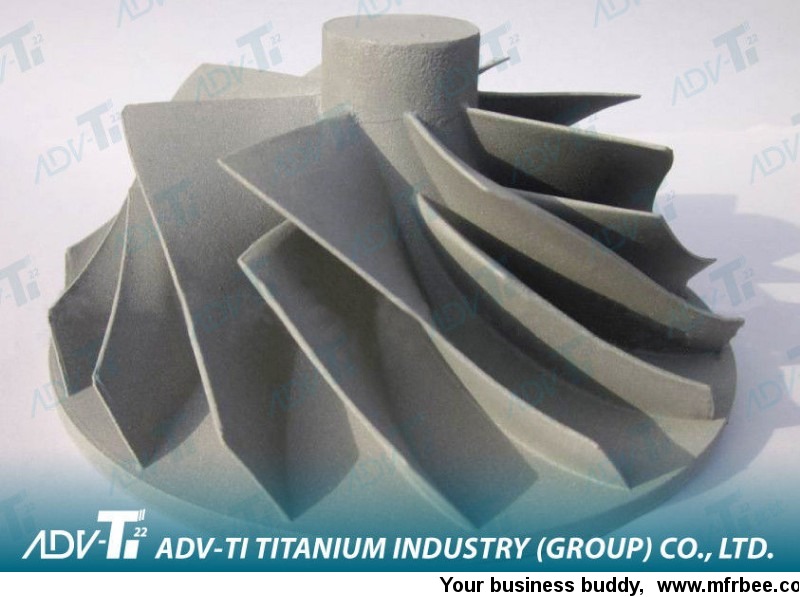

Diameter 1200mm×600mm High Temperature Alloy Casting

Product Quick Detail

- Packaging

- Export standard packed in wooden cases or as customer requirment

- Delivery

- The fastest

Specifications

Specifications

Casting

Nickel alloys: M35-1 (Alloy 400) M35-2 M30H(Monel 500) M25S M30C

*Vaccum precision castings for valve component

0.8mm Minimum thickness of Casting

Casting

1.Material

| Grade | CZ100 | M35-1 | M35-2 | M30H | M25S | M30C |

| UNS NO. | N02100 | N24135 | N04020 | N24030 | N24025 | N24130 |

| Generic designation | Alloy 200 | Alloy 400 | Monel 500 | Alloy S | ||

| Wrought tradename | Nickel 200 | Monel 400 | Monel | H-Monel | S-Monel | Weldable Monel |

The Minimum thickness of Casting: 0.8mm

The Max size of Casting: diameter 1200mm×600mm

The weight of Casting: 0.001kg~50kg

Surface Roughness: Ra3.2~6.3μm

2.Feature: Extremely resistant to abrasion, high temperature, thermal shock and oxidation.

3.Process: Investment casting, Vaccum precision casting

4.Valve accessories, like stems, valve caps, bolts of living, shafts; Pumps, pipes, and other components are available.We also supply other alloys as per the specified requirements of different shapes and sizes of our clients.

The Minimum thickness of Casting: 0.8mm

The Max size of Casting: diameter 1200mm×600mm

The weight of Casting: 0.001kg~50kg

Surface Roughness: Ra3.2~6.3μm

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: Worldwide,G20

- Founded Year: 2007

- Address: No21 Changjiang Road The National High-tech Development Zone

- Contact: Ada Shi