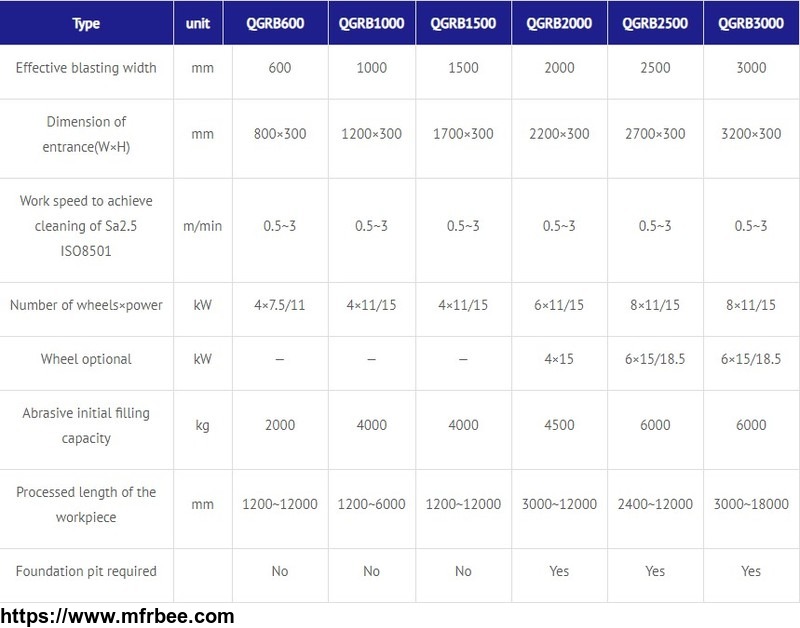

steel plate shot blasting machine

Product Quick Detail

- FOB Price

- USD $20,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Conveying system:

Component: rollers, chain, reducer, sprocket cover, and roller support.

-

A roller is first welding and then processing, to ensure the concentricity of the roller

-

The material of roller is 45# carbon steel, it can use 8-10 years.

-

Both sides of the roller are equipped with sprocket covers to protect the sprockets and spindle nose.

-

The roller support has secondary reinforcement, it is enough to load the workpiece.

-

The engineering team uses 3-D dynamic simulation design blast turbines layout to ensure that the steel shot ray can cover the surface of the workpiece 360 degrees.

-

Shot blasting chamber with ZGMn13 steel guard plate, long service life.

-

Six layers of protection curtain to prevent the shot balls spatter out during blast cleaning. The curtain layers are natural rubber material with leaf spring which can automatically reset, ensure the sealing of the machine.

- High chrome wear-resistant cast iron grate guard plate which protects the screw conveyor and prevents big clump to get into the hopper damaging the bottom screw conveyor.

Abrasive cleaning up system:

Abrasive cleaning up system consists of brush, screw conveyor, abrasive blowing fan and lifting mechanism. This system can remove the steel shot left on the plate after blasting.

-

The material of brush is high strength polyamide nylon, it has enough elasticity to sweep the 95% abrasive accumulated on the steel plate into the screw conveyor.

-

High-pressure abrasive blowing fan blows off un-collected steel shot on the plate to brush. In this way, the whole system recycles all the abrasive from the steel plate.

-

The lifting mechanism can automatically adjust the height of the brush, screw and abrasive blowing fan according to the thickness of the steel plate, to meet the needs of the customer.

- Country: China (Mainland)

- Contact: Joanna Yu