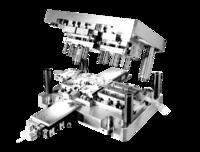

16 Pin Molded OBD Connectors for Automotive

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- 1.Coating oiling to form a protective coating against rust, corrosion, etc 2.Packed with pearl cotton to shake proof 3.Packed in

- Delivery

- 15 Days

Specifications

16 Pin Molded OBD Connectors for Automotive

zewivyizef

| Mould type | Injection mould,blew mould,die casting,compression mould,overmoulding,insert moulding,vaccum forming mould,etc |

| Mould steel | P20,H13,718H,2738,SKD61,NAK80,8407,S136H,etc |

| Plastic material | ABS,PC,PE,PP,HDPE,PPR,PVC,PBT,PS,PET,etc |

| Mould base | LKM,HASCO |

| Mould runner | Cold runner and hot runner |

| Mould Hot runner | DME,HASCO,YUDO |

| Mould cold runner | Point way,side way,follow way,direct gate way |

| Mould standard parts | DME,HASCO |

| Mould life | >300,000shots |

| Design software | Solidworks,UG,Pro-E,CAD |

| Mould doff way | Doff plate,ejectors,air valves,hydraulic jar |

| Mould hot treatment | Including quencher,nitridation,tempering |

| Mould cooling system | Water cooling or beryllium bronze cooling |

| Surface treatment | Paint,texture,polish,print,anodize,electroplating,electroforming |

| Hardness of the steel | 20-60HRC |

Key Specifications/Special Features:

1. Mold-flow system is used for mold design.

2. More than 15 years in field experience in mold and part fabrication.

3. Professional sales and skillful project engineers team to ensure NPI progress well.

4. We use authorized CAD.

5. High accuracy Japanese machines for production.

6. QR code is used in production between different processes.

7. Small orders are accepted.

On the premise of guaranteeing product quality, we have stable delivery date and thoughtful after-sales service to ensure your satisfaction and reassurance.

We hope to find long-term cooperation customers, mutual benefit and win-win situation, look forward to working with you.

- Country: China (Mainland)

- Founded Year: 2007

- Address: No.62, Jinghai East Road, Shatou District, Changan Town, Dongguan City, Guangdong Province, China

- Contact: Alisa chen