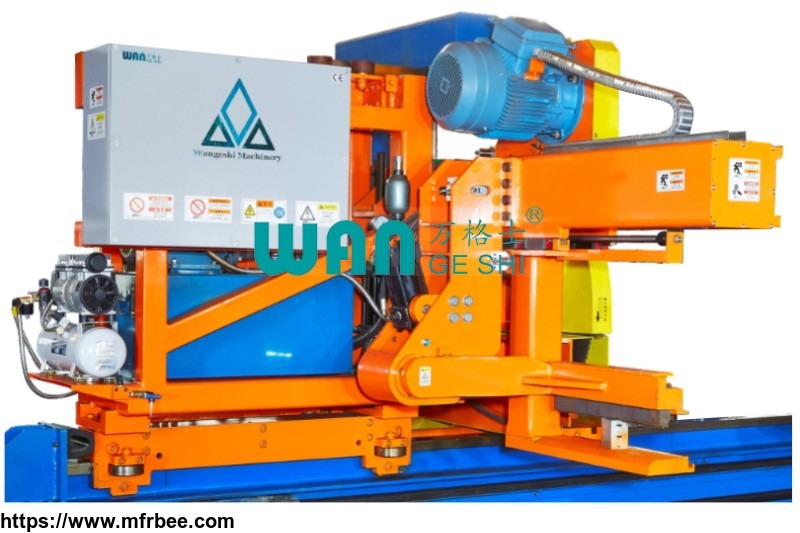

double head puller for alumininium extrustion profile

Product Quick Detail

- FOB Price

- USD $20,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- stand export pakage

- Delivery

- 30 Days

Specifications

| Matched extrusion press capacity | 600~5000 T |

| Matched cooling table height | 820mm (roller upper surface to ground) |

| Matched run out table external width | ≤510mm (roller width 400mm) |

| Matched lead out table length | 14-16 meters(excluding quenching length) |

| Pulling (cooling table)length | 26~38 meters |

| Maximum profile cross section | W250mm x H160mm |

| Synchronous pulling force | 0~100 kg |

| Synchronous pulling speed | 0~60m/min |

| Fast return speed | 0~260m/min |

| Sawing dscard length | ≈300mm |

| Sawing linear speed | ≈2000m/min (samll saw blade stress, longer use life, smoother profile cut surface) |

| Sawing advance speed | ≤350mm/s 3 options for variable profile thickness |

| Compessed air | 5~8kg/cm2, ≈0.3m3/h |

| Pulling motor power | 7.5kw x 2 |

| Vehicle hydraulic system power | 1.5kw x 2 |

| Hot saw motor power | 2.2 kw |

| Saw electric lubrication spraying power | 0.09kw |

| Control system | OMRON |

| Total weight | ≈15 Ton |

| Dimension |

53 m x 1.4 m x 1.8m |

| Features | Advantages |

| 2 pulling heads in the same rail | Can equipped with lift roller initial table |

|

Reduce 2-3% waste compared with single puller, reduce

6% waste compared with no puller. Full use of time, improve productivity. |

|

| Track is of high degree accuracy, pulling head is lightweight designed by computer finite element analysis | |

| Able to seek dead-cycle time & weld mark | Improve productivity, shorten dead cycle time |

| Specific hydraulic system design | Low/medium/high speed options for sawing speed, shorten production period; adjustable travel-type clamping cylinder, prevent profile from squeezing; When pulling profiles, clamping cylinder stores energy and keep pressure, oil pump motor stops working, that can prevent over high temperature, meanwhile save electricity power. hydraulic pipe layout is neat and reasonable, easy for maintenance. |

|

Innovative design

for main saw spindle |

Easy and fast to change the belt and easy maintenance |

| Equipped with electric sawing lubrication system | Spray nozzle lubrication, longer use life of saw, more smooth surface for the profile |

| 8 types of pulling mode | Flexible to choose the best mode |

| Built-in self-diagnostic system | Identify fault quickly |

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia,Middle East,European Union

- Founded Year: 2005

- Address: hengang industry zone Nahai district

- Contact: jk louis