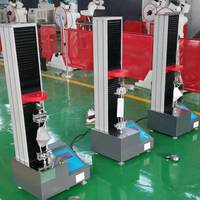

Face Mask Tensile Testing Machine

Product Quick Detail

- FOB Price

- USD $8,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Inner package: pp film Outside package: standard export wooden case

- Delivery

- 15 Days

Specifications

Face Mask Tensile Testing Machine is a new material testing machine which combines electronic technology with software technology and mechanical transmission, and adopts stepping motor

system as precise power source; Adopt precision ball screw and guide rod, adopt 0.5-level precision force sensor, and realize accurate measurement through high-precision force measurement system.

Detailed introduction of Face Mask Tensile Testing Machine:

The medical mask tensile testing machine is mainly used to test the tensile strength of various masks and protective clothing such as medical masks, disposable masks, goggles and protective

clothing, and also to test the tensile, tearing, elongation and peeling mechanical properties of plastic, woven bags, nonwovens, plastic films, products, PVC pipes, paper and paperboard, woven

bags, packing tapes, tapes and adhesives.

It is a new material testing machine which combines electronic technology with software technology and mechanical transmission, and adopts stepping motor system as precise power source; Adopt

precision ball screw and guide rod, adopt 0.5-level precision force sensor, and realize accurate measurement through high-precision force measurement system.

Mask inspection:

Mask types: 10N for 10s;;

Disposable mask: 50N for 10 s;

Replaceable mask: 50N for 10 s;

Comprehensive cover: 150N for 10s.

Applicable standards:

YY/T 0469-2011 Medical Surgical Mask

YY/T 0969-2013 Disposable Medical Mask

GB/T 19083-2010 technical requirements for medical protective masks

GB/T 32610-2016 technical specification for daily protective masks

GB/T 2626-2019 respiratory protection self-priming filter respirator for preventing particulate matter

GB/T 19082-2009 technical requirements for medical disposable protective clothing

GB/T 10213-2006 disposable medical rubber inspection gloves

Technical parameters:

1. Accuracy grade: 0.5;

2. Optional range: 5-2000 N;

3. Effective force measuring range: 0.2/100-100/%;

4. Test result unit selection: gf, kgf, N, KN, LB;

5. Test force resolution, load 500,000 yards: internal and external files are not graded, and the whole resolution is unchanged;

6. Effective test width: 150mm, effective stretching space: 800mm;;

7. Test speed: 0.01~500mm/min (arbitrarily adjusted);

8. Speed accuracy: within 0.5% of the indicated value;

9. Displacement measurement accuracy: within 0.5% of the indicated value;

10. Deformation measurement accuracy: within 0.5% of the indicated value;

11. power supply: 200V, 400W.

- Contact: QIAN qian