Fried Banana Plantain Chips Production Line | Processing Plant

Product Quick Detail

- Price1

- 100

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Classifications of Taizy banana plantain chips production lines

As a strong food machinery manufacturer and supplier, Taizy factory currently mainly provides small semi-automatic banana chip production lines (100kg/h to 500kg/h) and large fully automatic fried plantain chips production lines (200kg/h to 1000kg/h) to customers at home and abroad.

Equipment list of the semi-automatic banana chips production line

| No. | Equipment name |

| 1 | Green banana peeling machine |

| 2 | Banana slicer machine |

| 3 | Banana chips blanching machine |

| 4 | Banana chips dewater machine |

| 5 | Banana chips fryer machine |

| 6 | Fried banana chips deoiling machine |

| 7 | Fried banana chips seasoning machine |

| 8 | Fried banana chips vacuum packaging machine |

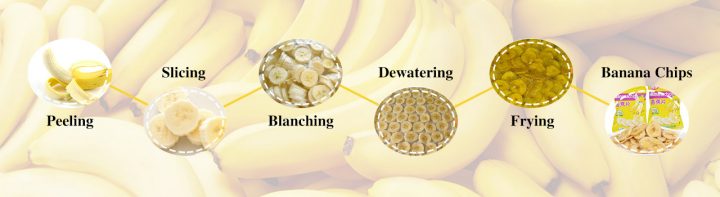

The production process of small fried banana chips processing line

The production process of the deep-fried banana chips processing line is simple and easy for the producer to operate. The production process mainly includes banana peeling, banana slicing, banana chips blanching, banana chips dewatering, chips frying, fried banana chips deoiling, fried banana chips seasoning, fried banana chips packaging, etc.

1.Banana peeler machine

Banana peeling machine is mainly used for batch peeling of bananas. The bananas used to make crisp banana chips are preferably fresh, non-damaging bananas with a maturity of 70 to 80%. Less ripe green bananas can also be used to make fried banana chips.

2. Banana slicer machine

This electric banana slicer machine is the commonly used slicing equipment for making all kinds of vegetable and fruit slices. It can make banana chips with a thickness of 5-8mm very quickly. After slicing, the producer can soake them in a sodium bisulfite solution with a concentration of 5-10% for 30-50 minutes for good tastes and colors.

3. Banana chips blanching machine

After slicing, these banana chips should be blanched with the electric blanching machine to remove the excess starch and debris. The banana chips are lightly blanched to ensure that they taste more delicious after frying.

4. Banana chips dewatering machine

Before frying these banana slices, we also need a fast dewatering machineto remove the water droplets of the banana chips. Therefore, when frying the banana chips, it will be more efficient and safe.

5. Banana chips fryer machine

Banana chips frying is the most important step of the semi-automatic banana chips production line. The heating methods of this fryer machine can be both electricity and liquified gas. Within 5-6 minutes frying with the temperature around 160 ℃, the crisp deep-fried banana chips will be finished.

6. Fried banana chips deoiling machine

After the deep-frying of the banana chips, the users should use an automatic deoiling machine for reducing the excess oil of the fried banana chips. So that can keep the good tastes of the banana chips.

7. Fried banana chips seasoning machine

By using this continuous seasoning machine, the banana chips producers can make their chips with different flavors. The banana chips seasoning machine has high efficiency of mixing the chips with seasonings fast and evenly.

8. Fried plantain chips packaging machine

The last step for processing banana chips is to pack these delicious chips into bags with the fully automatic intelligent packaging machine . It is often used in large potato chip production plants. Products packed with this automatic weighing and packaging machine not only have a very low breakage rate, but also pack quickly.

Machine list of large fried plantain chips processing plant

| No. | Equipment name |

| 1 | Green banana peeler |

| 2 | Banana slice cutter machine |

| 3 | Hoist conveyor 1 |

| 4 | Belt type banana chips blanching machine |

| 5 | Plantain chips air-drying and cooling machine |

| 6 | Hoist conveyor 2 |

| 7 | Leaching sugar machine |

| 8 | Hoist conveyor 3 |

| 9 | Belt type continuous frying machine |

| 10 | Fried banana chips deoiling machine |

| 11 | Hoist conveyor 4 |

| 12 | Fried plantain chips seasoning machine |

| 13 | Automatic banana chips packaging machine |

Full-automatic banana plantain chips production line’s features

- 1. A larger green banana peeler machine is needed for the automatic plantain chips line. This machine has different types and models as well as different capacities. It has two inlets with different diameters, which is suitable for peeling bananas of different sizes. And it needs at least 2 workers when working.

- 2. The electric hoist conveyors are required for the fried plantain chips production line. To achieve automatic production of banana chips, the conveyors will be very useful to reduce worker participation. And this banana chips line needs no less than 4 hoist conveyors for connecting each of the banana chip processing links.

- 3. Continuous plantain banana chips frying machine is the key equipment for full-automatic banana chip processing plant. The mesh belt fryer can work continuously, and the frying process does not require workers to participate, which can ensure the safety of the fried banana chip production process. The temperature of the plantain chips fryer can be set and adjusted between 100°C and 200°C. The oil residue formed after frying can be easily removed.

- 4. The main purpose of sugar dipping and seasoning in the production process of fried banana chips is to make fried plantain chips with a better taste. In actual production, customers can choose whether to dip banana chips with sugar and seasoning.

- 5. In order to meet the commercial production of crisp banana chips, we usually need to equip a large banana chip packaging machine. This continuous packaging machine can pack banana chip snacks into bags of various specifications. We can customize the weight of each bag of banana chips, the style and size of the packaging bag, etc. according to the packaging needs of customers.

- Contact: angel zhou