Engine Bottom Shell

Specifications

Engine Bottom Shell

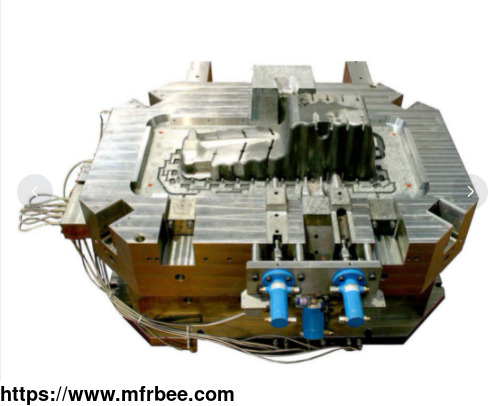

Partial Aluminum Mold Casting of Engine Bottom Shell

As one of the professional aluminum stamping companies, we guarantee aluminum stamping press are of high quality with outstanding terminal stamping service

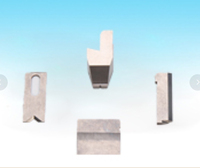

Advantages of Aluminum Stamping to Engine Bottom Shell

Replacing the traditional steel structure with aluminum stamping structure can reduce the mass of the engine bottom shell by 30%-40%,The use of aluminum alloys is one of the important ways for

automobiles to be lightweight, environmentally friendly, energy-saving, speed-up, and efficient in transportation. By doping alloy elements and cold work hardening, the strength of the alloy can be

doubled. Some heat-treated damage of engine bottom shell using aluminum stamping press part has a tensile strength of 700 MPa. The aluminum stamping used to engine bottom also has good heat

dissipation. Using an engine bottom shell of aluminum stamping is the best solution to generat more heat. It has become a mainstream trend to use aluminum stamping instead of cast iron in engine

bottom shell.

Description of Aluminum Stamping

Aluminum stamping mould production procedures aredivided into: incoming materials, unstacking and splitting, centering, drawing, trimming and punching, inspection, packing, and auxiliary processes

iinclude mold repair, workpiece repair, etc. The aluminum stamping press is the key equipment for stamping production, and the requirements of the aluminum alloy for the press are mainly reflected

in the first one. The first one was a multi-link press, of which eight-link and six-link presses were more common. With the application of servo control technology, imported and domestic

large-tonnage servo presses have also been recognized by many aluminum stamping companies.

If you want to know more about himo industry, please visit our website.

- Country: China (Mainland)

- Founded Year: 2018

- Contact: Yokini Wang