Engine Bottom Shell

Specifications

Engine Cylinder Block

Engine Block With Sufficient Strength And Rigidity And Long Service Life

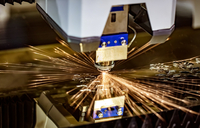

Engine block mold is mainly used to manufacture engine blocks in the sand casting process. With high-efficiency engine block molds, blocks can be created in mass production.

Description of Engine Cylinder Block Mold

Engine cylinder block is one of the most important parts in the engine due to the large size and complex structure. The thin wall thickness and uneven surface of the engine block also make it

difficult to manufacture parts without engine block casting technology. It is typical complex casting for its narrow process scope. Therefore, it is much more suitable for the production of engine

block mold casting to solve all above problems. Considering the characteristics and subsequent production, engine block casting technology is adopted with a reasonable structure design. This engine

block mold casting design is conducive to improve the qualified rate and comprehensive performance of the engine block.

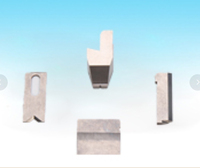

Advantages of COSMOPlat Engine Block Casting

Different high-quality materials of engine block castings are available in COSMOPlat with unique features. We aim at providing excellent and well-quipped engine block casting and good services.

1.Aluminum alloy cylinder block

·Good heat transfer performance

It is conducive to improve the compression ratio of the engine block casting.

·Save the fuel of the engine

Now the fuel consumption pressure is relatively large, and lightweight is a way to reduce fuel consumption of engine block casting.

2.Cast iron cylinder block

·Good strength and stiffness

The cast iron cylinder block is powerful in rigidity. Engine block casting has low vibration noise during working.

·Low process requirements

Using the cylinder liner structure, the kind of engine block casting bloc is directly operated in the cylinder body surface.

As a China mold company, we will provide you the best internet experience. If you have needs, please contact us.

- Country: China (Mainland)

- Founded Year: 2018

- Contact: Yokini Wang