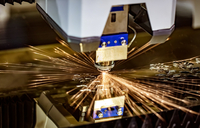

Precision Parts

Specifications

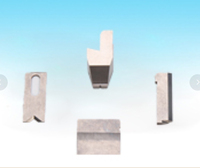

Precision Mould Parts

Various high-precision parts

As a precision molding company, we spare no efforts to provide precision moulded components to achieve our customers' satisfaction. If you have any questions about our parker precision molding,

please do not hesitate to contact us!

Precision Molding Overview

Among the relevant factors affecting precision plastic injection moulding, the mold is the key to obtain precision injection products that meet the quality requirements. The design of the presicion

injection mold, whether the mold design is reasonable or not, will directly affect the quality of plastic products. Since the mold cavity size is derived from the required size of the plastic

product plus the shrinkage rate of the material used, and the shrinkage rate is often a range of values recommended by the plastic manufacturer or engineering plastics manual, it is not only

related to the mold gate form, gate location and distribution, but also related to the crystalline orientation of engineering plastics (anisotropy), the shape and size of the plastic product to the

distance and location of the gate.

Influence Factors of Precision Molding

Precision injection molding is affected by many related factors and environmental conditions, and the most basic ones are plastic materials, injection molds, injection molding process and injection

molding equipment. In the early stage of designing plastic products, the engineering plastics that can be required are firstly selected according to their environment. Next, the selected plastic

material, finished product dimensional accuracy, part weight, quality requirements and the expected mold structure to choose the appropriate precision mould in china parts.

If you want to know more about 3d printing solutions, please contact us.

- Country: China (Mainland)

- Founded Year: 2018

- Contact: Yokini Wang