SDS Loose Hooked End Steel Fiber

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Hooked end steel fibres

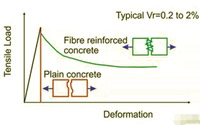

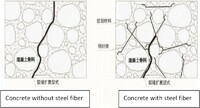

Unlike conventional reinforced fiber, steel fibers focus on three-dimensional reinforcement and make it impossible for a plain crack to follow.

Advantages of Loose Hooked End Steel Fiber

Technology advantage

The design of end hooks at both ends of steel fiber is the best anchoring design, which slowly deforms in the process of drawing, thus enhancing the binding force between hooked steel fiber and concrete.

Material advantage

SDS hooked steel fibre is made of high-quality wire by cold drawing, and its tensile strength is greater than 1100MPa, which ensures extremely small tolerance and high tensile strength.

Economic advantage

A.Compared with ordinary concrete, the same mixing and construction, do not need to add equipment.

B.Under the same strength, the concrete consumption can be saved

C.Replace or partially replace reinforcement

D. Shorten the construction period, especially suitable for large projects requiring continuous and rapid pouring of concrete.

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:2011

- Address:NO.397 Shunhe Road,Tengzhou Economic Development Zone,Shandong Province,China.

- Contact:cnsteelfiber

Other products from Tengzhou Star Smith Metal Products Co., Ltd

Relate products of SDS Loose Hooked End Steel Fiber

Hooked end steel fibres are made of high-quality cold drawn steel line, in order to make sure that it has high tensile strength and animal tolerance. And the steel fiber in bulk ensures the mixing fast and convenient, and the distribution homogeneous. During pulling from the ...

Glued hooked end steel fibre is made of high quality cold-drawn wire. The glued steel fiber in bulked could make sure it has good dispersibility in concrete. Compared with general concrete, steel fibre concrete has a great improvement in tensile strength, flextural strength, ...

This fiber is a high-performance steel fiber. Because of its high tensile strength, good toughness, and low price, it is often used as a substitute for glued steel fibers. It can be widely used on roads, highways, curbs, factory floors, airport runways and etc. If you are ...