Dutch Plain Weave Wire Mesh

Specifications

Supplied in stainless steel (SUS304L and 316) chiefly, the finished Dutch Plain wire mesh/cloth offers excellent acid and alkaline resistance. This type of wire cloth is most frequently used for high pressure filtration processer to separate one medium from other medium.

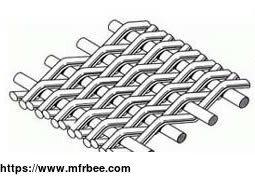

Weaving Method: Dutch plain woven wire mesh/cloth/fabric has straight warp wires and close weft wires.The weft wires lie as close as possible against each other in a linen weave forming a dense strong material with small, irregular and twisting passageways that appear triangular when diagonally viewing the weave .

Compared with normal Plain Weave

Features: Dutch plain woven wire is more solid than square or rectangular mesh, offering relatively high open area, suitable for all kinds of pressure filtration.

Uses: Dutch plain woven wire mesh is mainly used in the following fields:

1, Industrial filter cloth and apparatus of separation;

2, in gas and liquid filtration and other medium separation;

3, Precision pressure filters, the fuel filter, vacuum filter, as filter materials, aerospace, oil refining, pharmaceutical, sugaring, oil, chemical, chemical fiber, rubber, tire manufacturing,

metallurgy, food, health research,etc.

- Country: China (Mainland)

- Business Type: 制造商

- Market: Africa,Americas,Asia,Emerging Markets,Europe,European Union,G20,Middle East,Oceania

- Founded Year: 2000

- Address: No.156 Industrial Park,Dezhou,China

- Contact: Lu Feng